Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

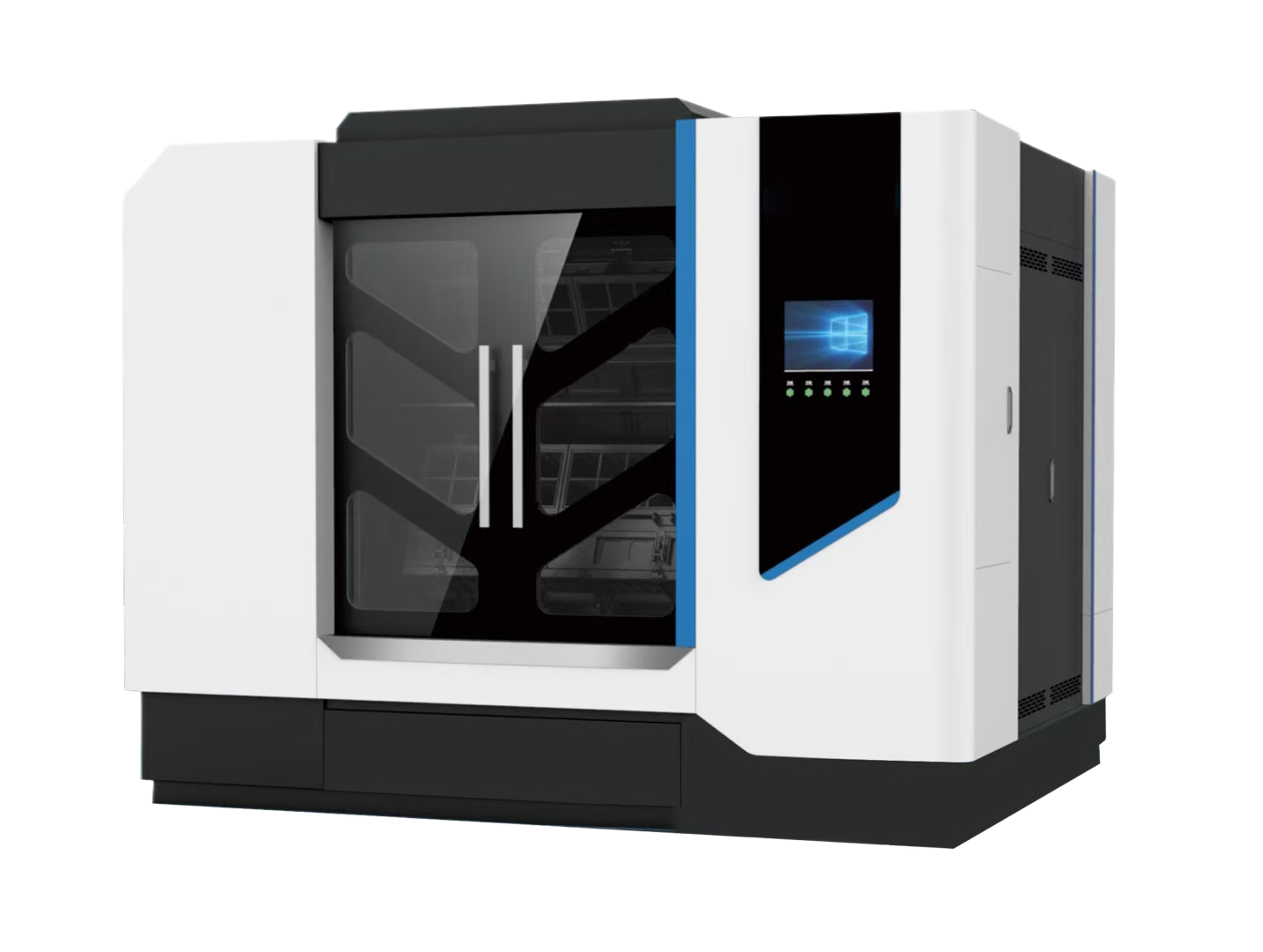

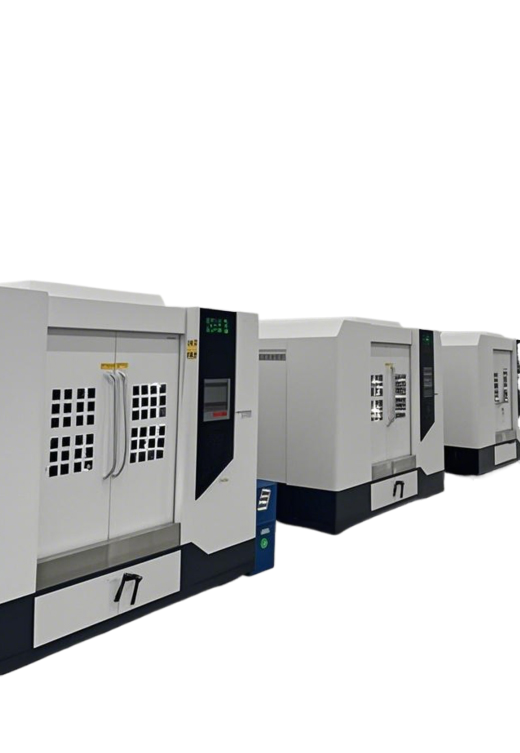

Hardware high speed polishing machine

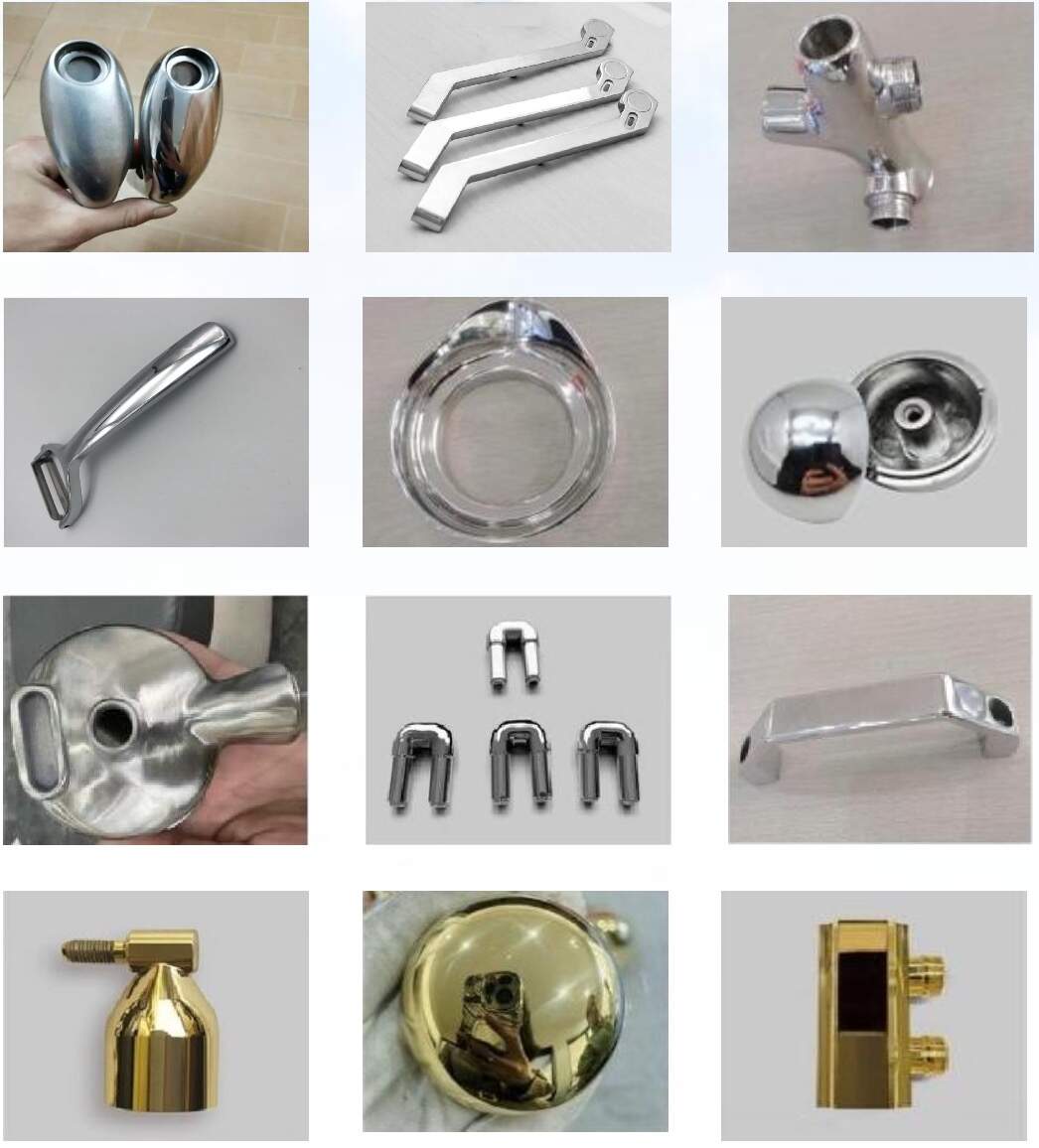

High-speed polishing for your hardwares, mirror polishing. It can deal with multi-quantity products one time.

Before painting, electroplating, or anodizing,using our machine to do polishing.

-

Product Overview

-

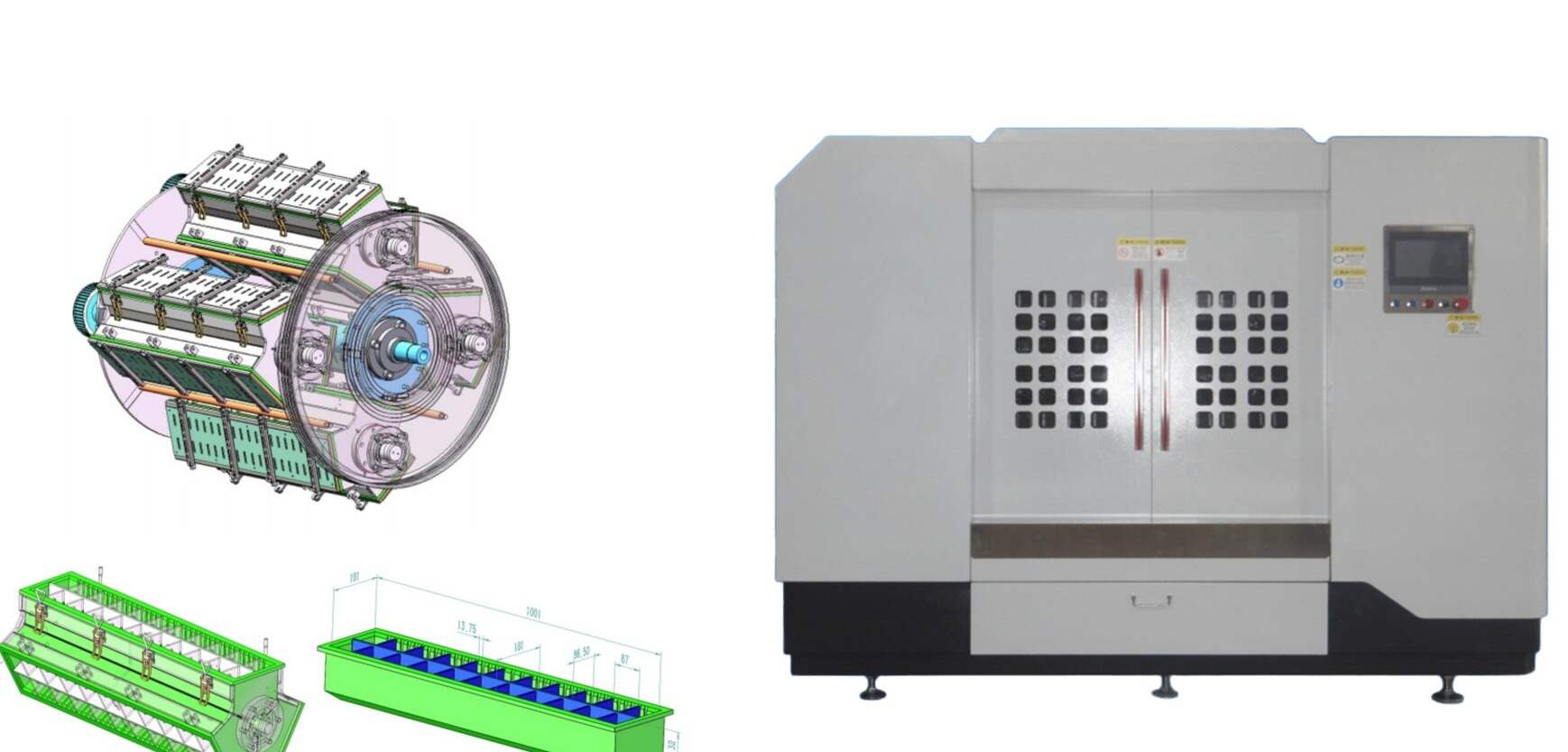

The high-speed series utilizes a unique centrifugal three-dimensional friction technique.

-

As an industrial-grade surface treatment apparatus, it can handle a diverse range of metal material products, such as zinc alloy, aluminum alloy, stainless steel, and copper alloy.

-

It is capable of performing crucial processes like deburring, rough polishing, fine polishing, and achieving a mirror finish on these metal items. Equipped with a state-of-the-art, fully enclosed dry-grinding system, the series high-speed polishing machine stands out for its environmental friendliness.

-

The system ensures zero discharge of wastewater and exhaust gas, and it maintains dust control at a level 80% lower than the industry standard.

-

With an operating noise kept below 75 decibels, it is an ideal option for companies committed to green and intelligent manufacturing.

-

Core Advantages

-

Intelligent and High-Efficiency, with Precise Control The PLC-based intelligent control system in the machine enables convenient parameter presetting. This industrial-grade surface treatment apparatus can achieve smooth automatic start-stop operations and features efficient fault diagnosis capabilities.

-

Paired with a user-friendly touch-screen interface, it allows for seamless human-machine interaction. The series High-speed polishing machine adopts a dual-axis linkage motion mode. The main shaft rotates at a speed ranging from 60 to 130 revolutions per minute (r/min), while the material bin rotates at 6 - 12 r/min.

-

This configuration ensures that workpieces are uniformly stressed at a full 360-degree angle.

-

The adaptive pressure compensation technology adjusts the grinding force according to the workpiece's material properties, preventing over - or under-grinding and guaranteeing high-quality processing.

-

Environmentally Friendly, Safe, and Reliable

-

The fully enclosed dry-grinding process of the series eliminates wastewater and exhaust gas emissions.

The dust emission of this industrial-grade surface treatment apparatus is maintained below 10mg/m³.

-

Biobased grinding consumables, made from natural and biodegradable materials, are used, ensuring no pollution.

-

Multiple safety protection measures, including a light-curtain sensor, overload protection device, and an emergency braking system, are installed to safeguard the operation environment.

-

Flexible and Versatile, Cost-Effective and Productivity-Boosting

-

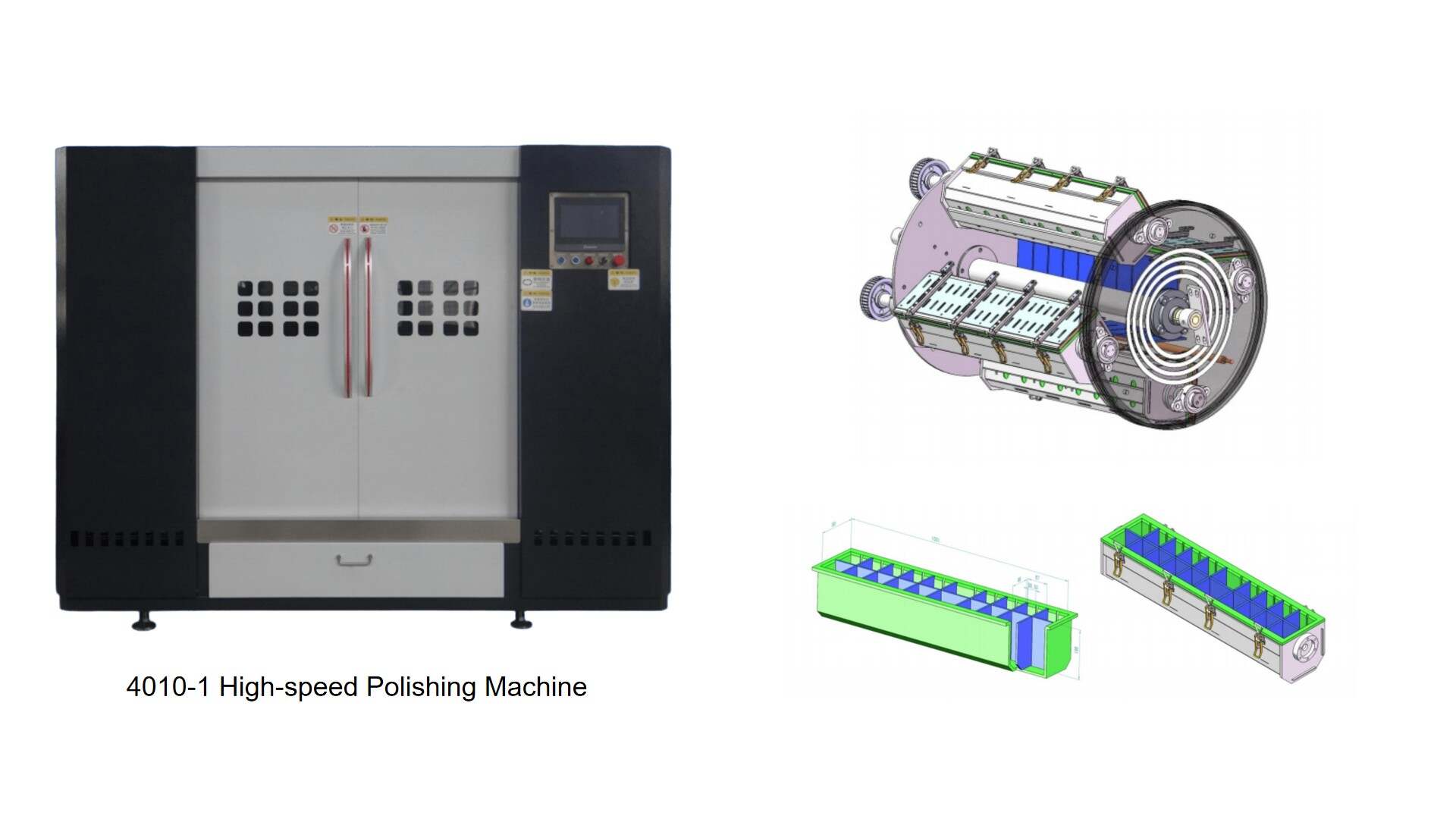

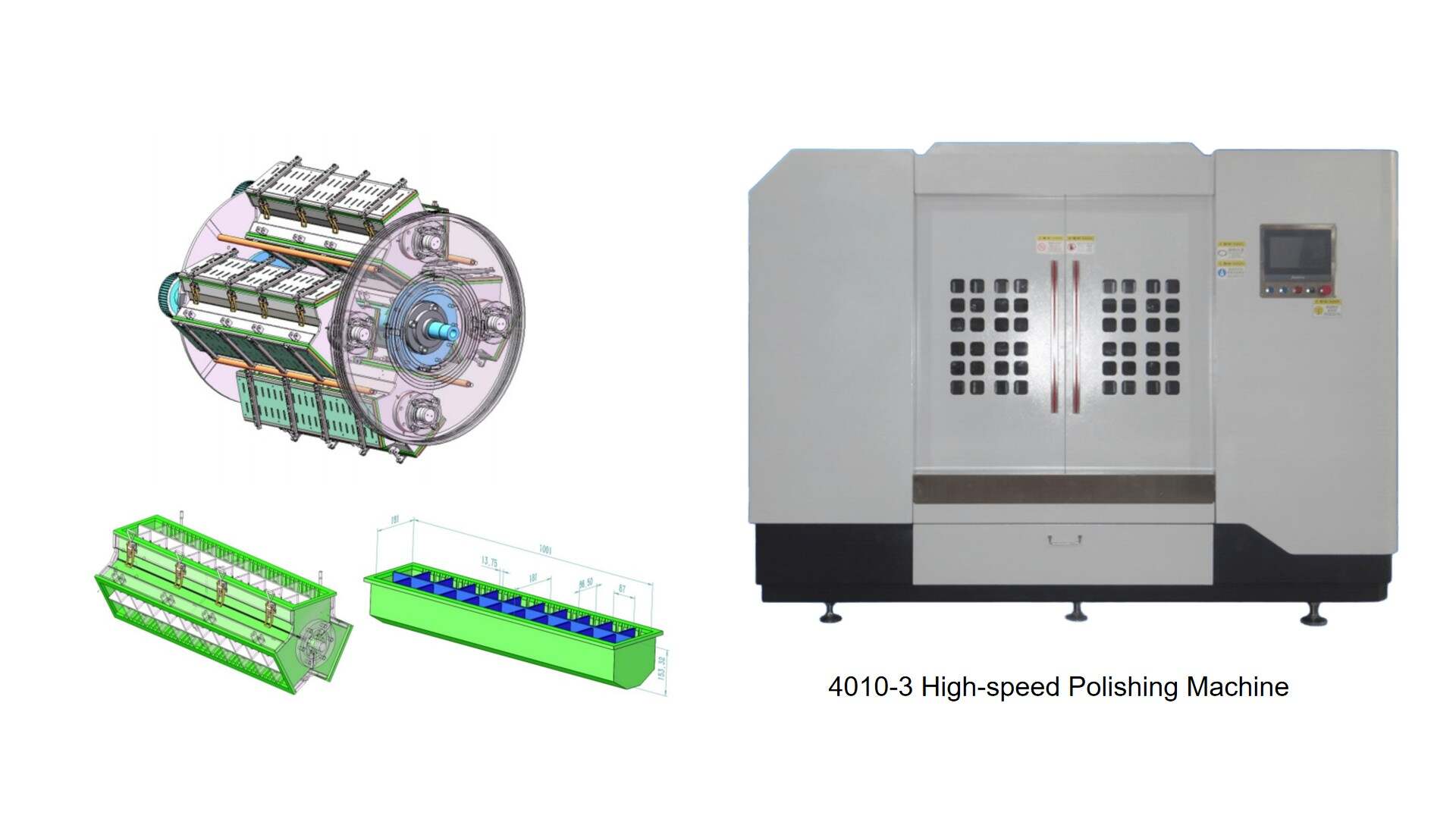

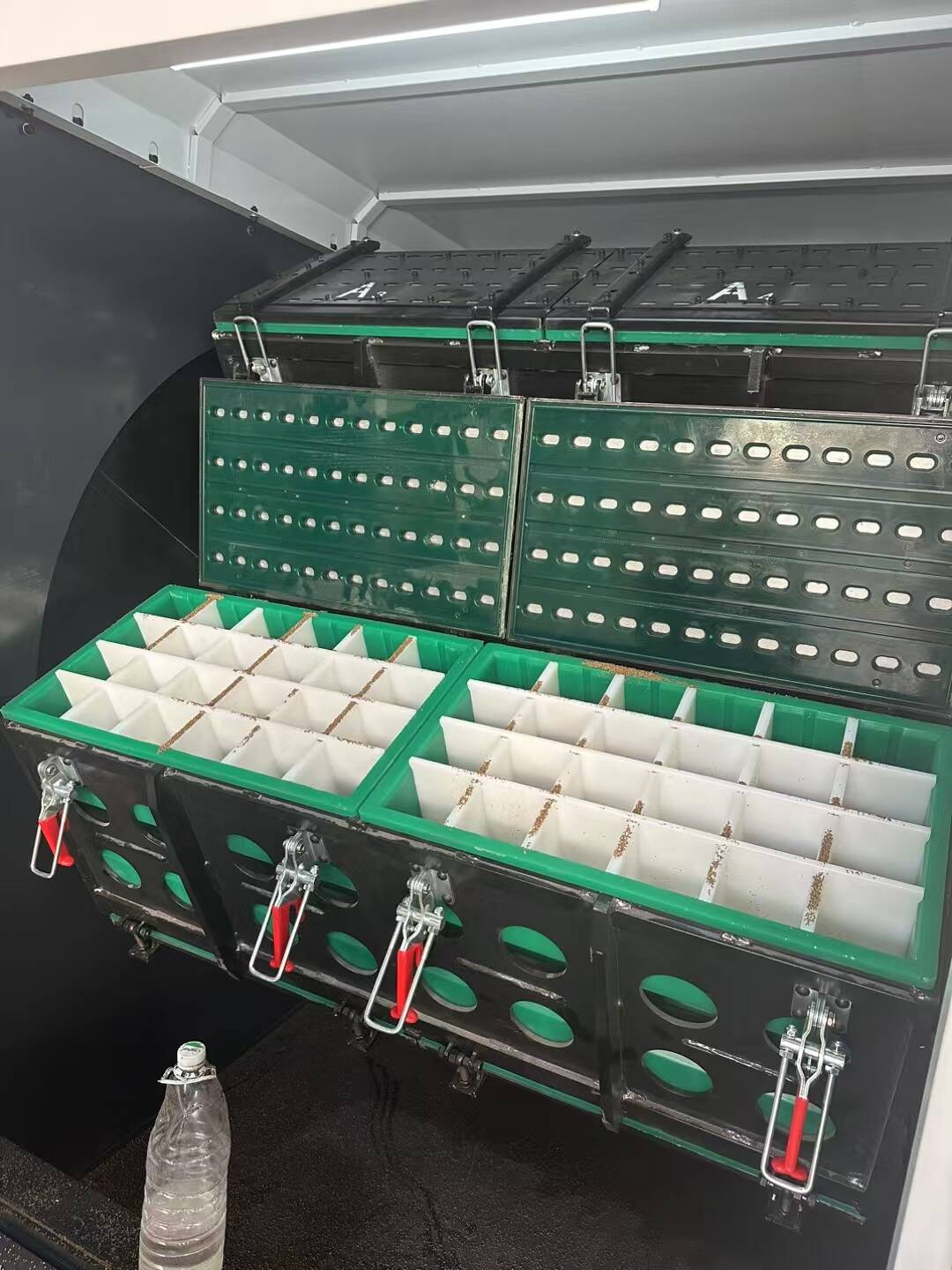

The modular design of the material bin in the series High-speed polishing machine features movable partitions that can be adjusted to create 12-78 compartments.

-

This makes the Industrial-grade surface treatment apparatus suitable for workpieces with diameters ranging from φ15 to 300mm.

-

The machine has a multi-specification processing capacity. The single-batch processing quantity can reach 50 - 500 pieces, and its efficiency is 300% higher than traditional processing methods.

-

The clamp-free design reduces fixture costs and enables direct processing of complex and irregularly shaped workpieces, enhancing the machine's versatility.

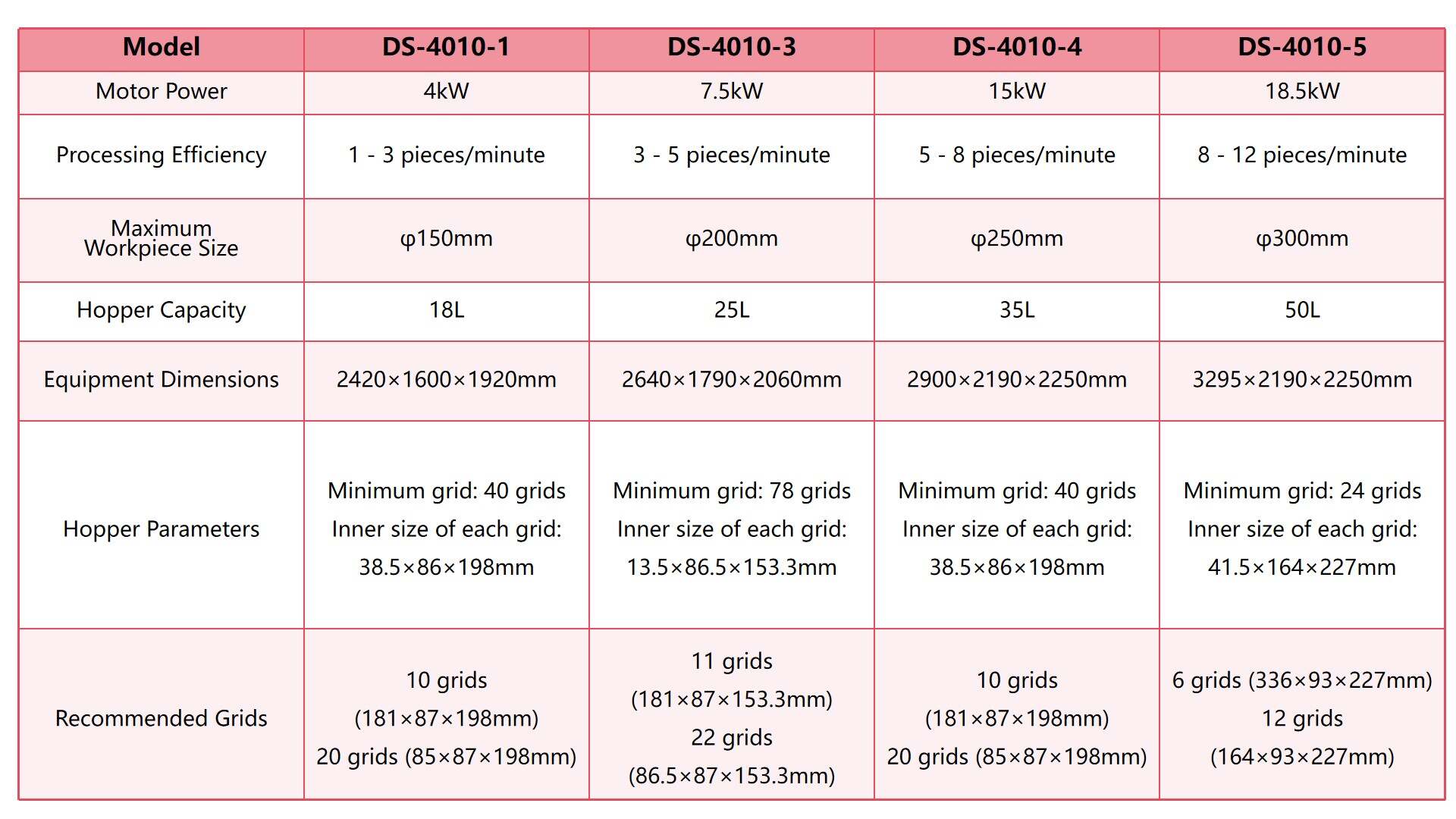

Parameters

Polishing effect

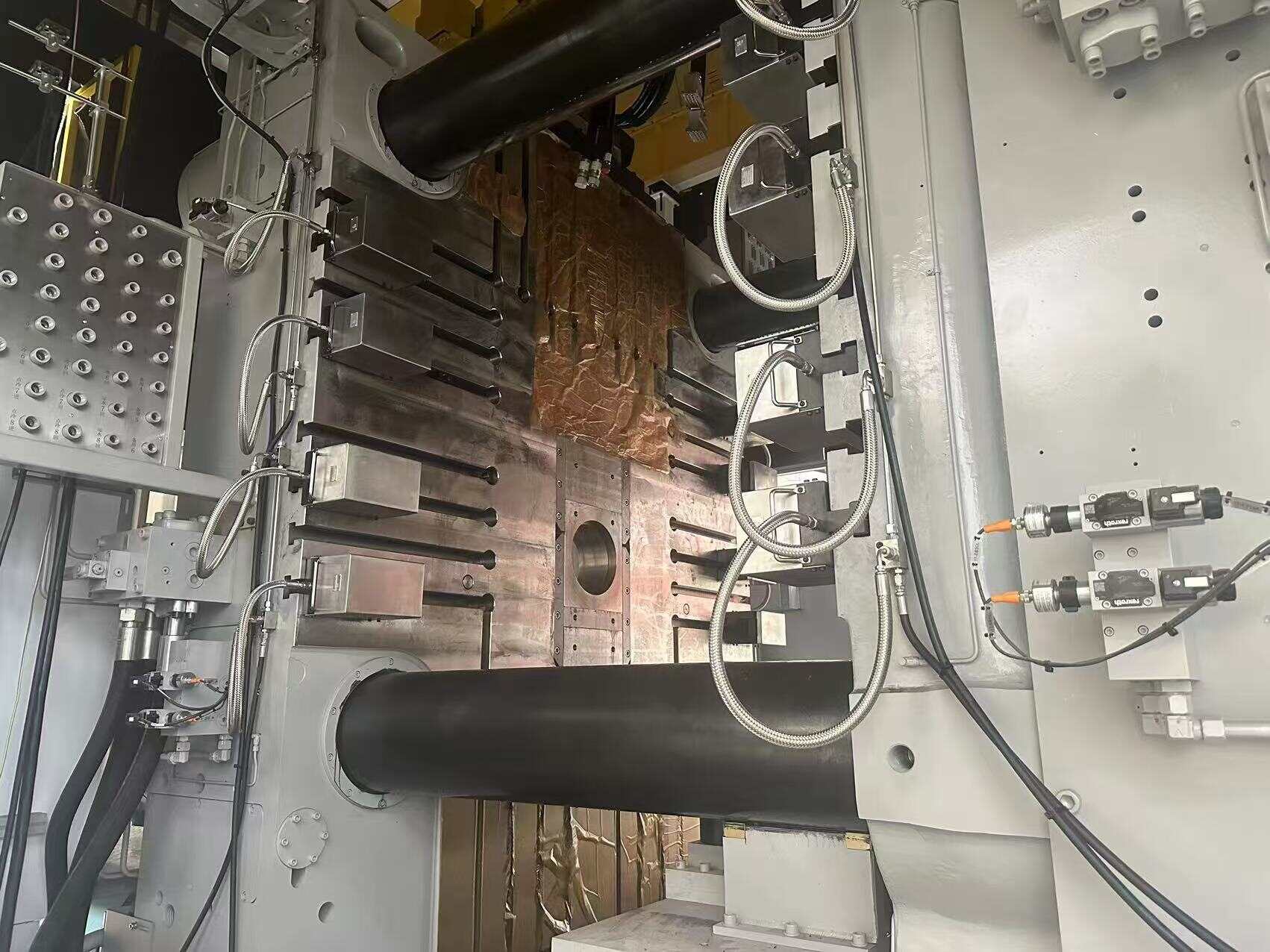

Customer site