Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

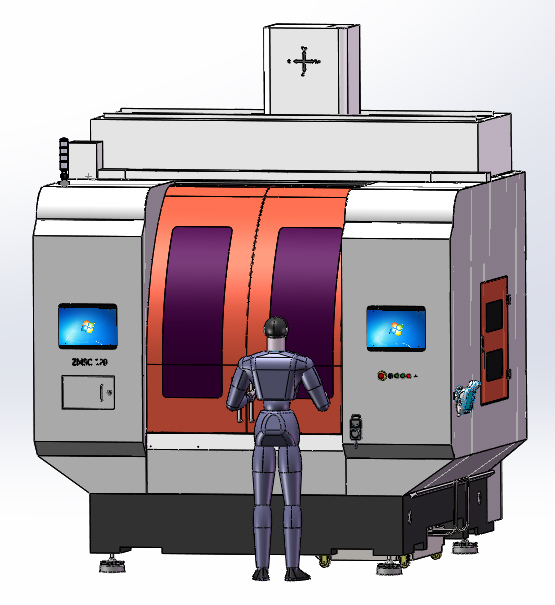

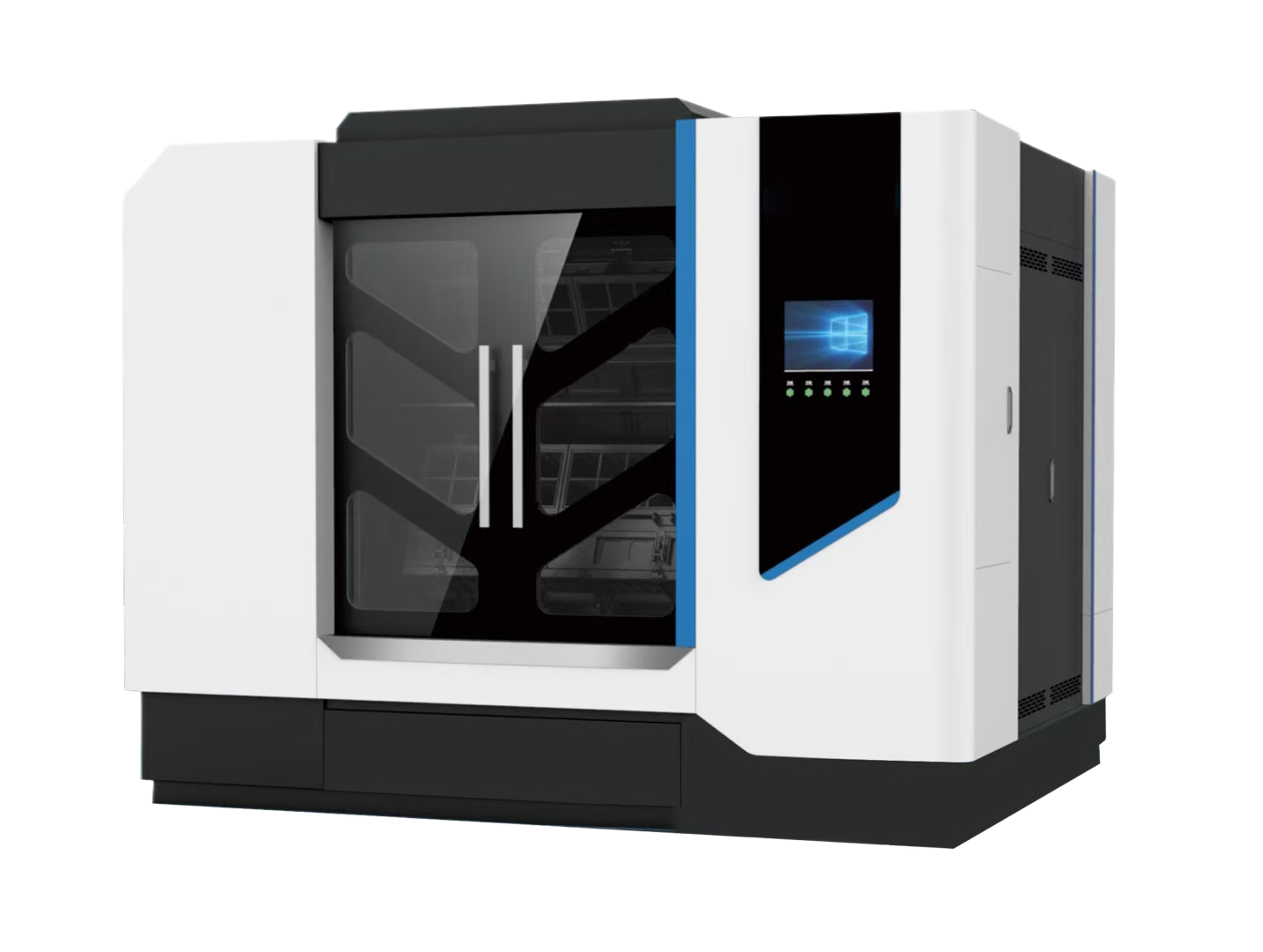

Big die casting parts deburring machine

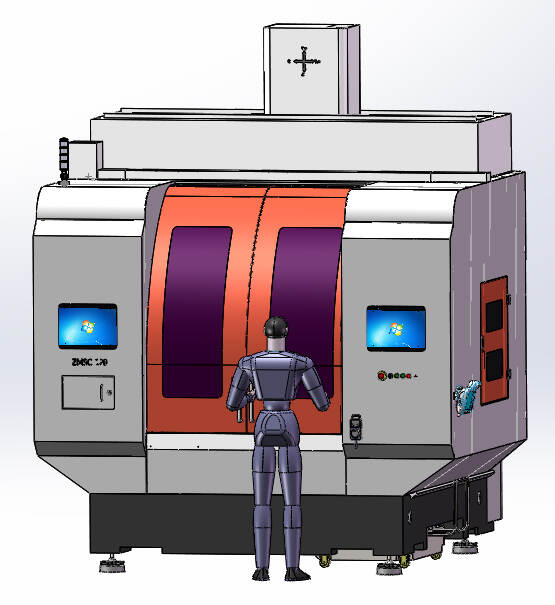

This machine can deal with big, heavy, and complex structure casting products over 1 meter long.

To solve the problems of deburring and grinding process for big and heavy casting parts, such as big automotive components.

Description:

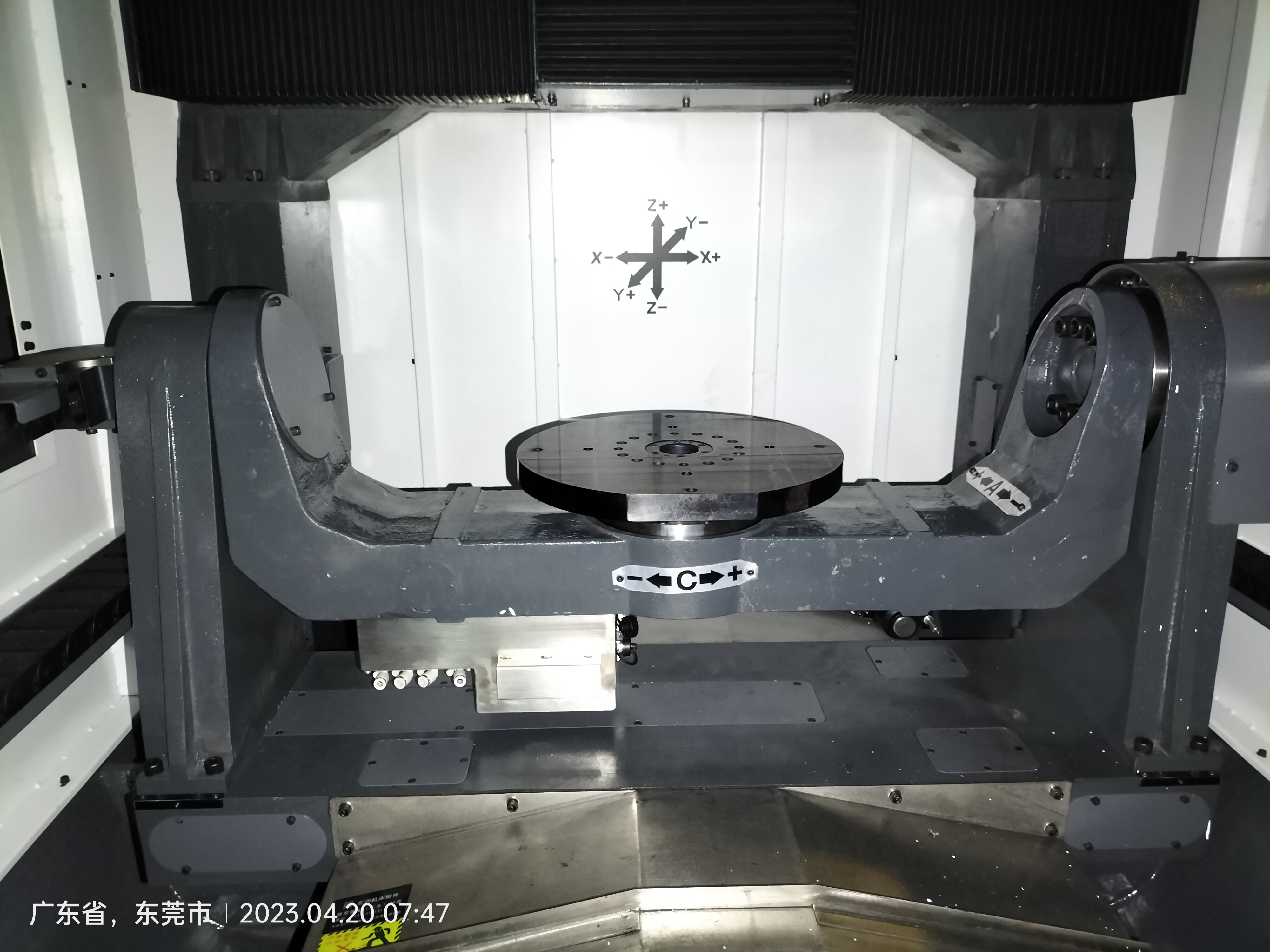

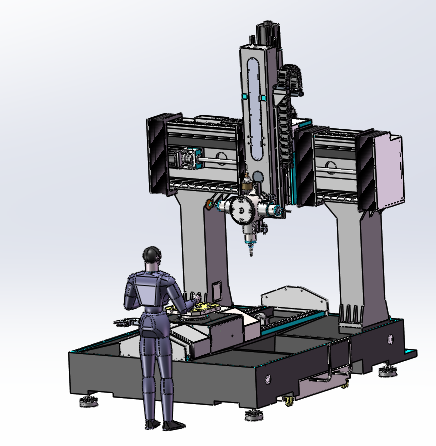

• This facility is a six-axis intelligent grinding machine that moves in X-axis, Y-axis, and Z-axis directions and rotates around B-axis and C-axis.

• This facility is a five-axis machining machine that can meet the one-time clamping of workpieces and achieve multi-directional grinding needs.

• This facility is equipped with a four-head or six-head rotary tool magazine, which eliminates the need to change tools at a fixed tool change position. It is fast, improves tool change efficiency, and can realize multi-angle inclined processing.

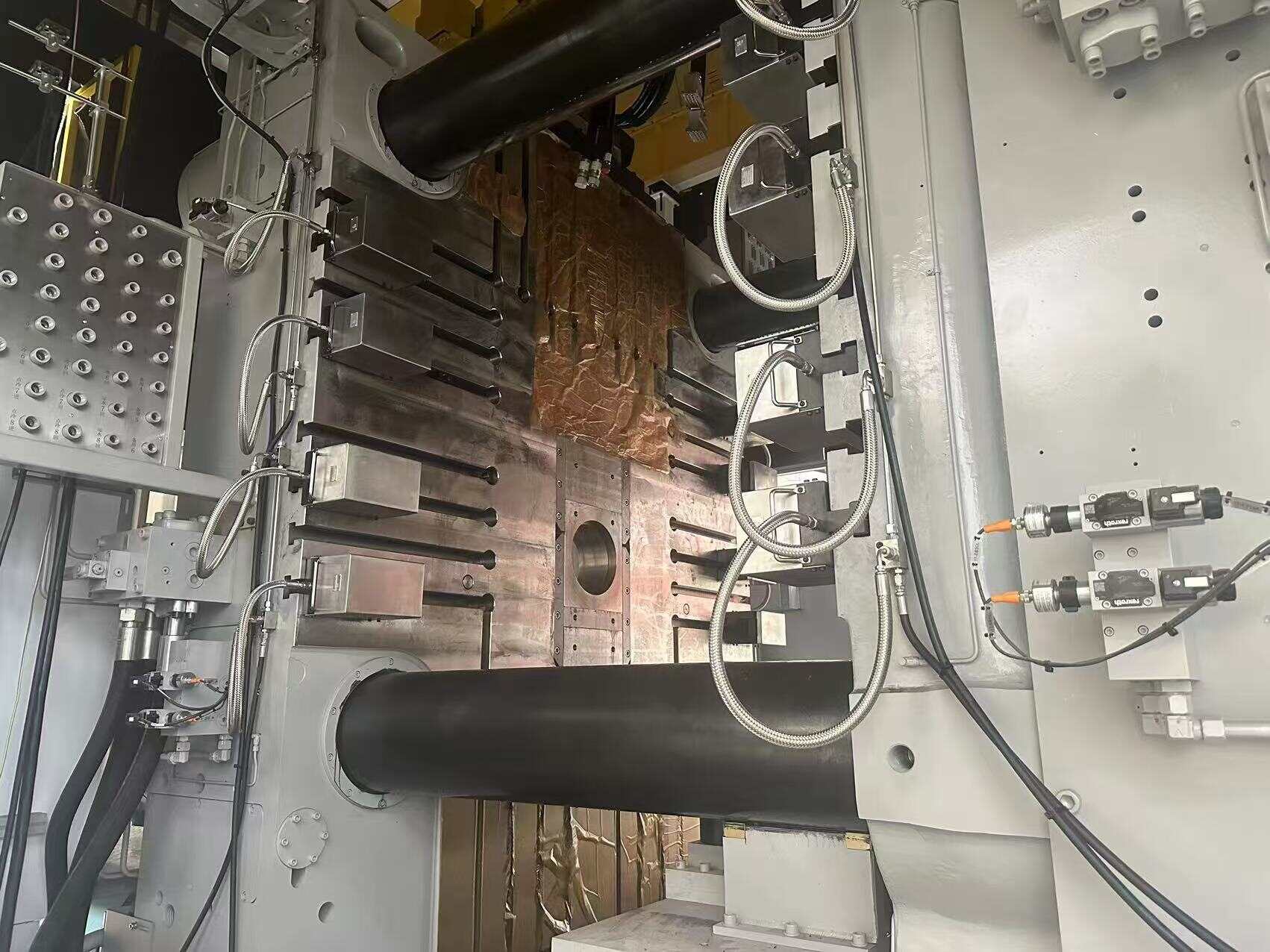

• The grinding and deburring tools can be flexibly replaced according to the processing requirements to realize the reasonable combination of flexible and rigid tools.

• The worktable is equipped with a tooling quick change locating pin, which can realize rapid switching and installation of tooling and reduce the time for repeated tool setting and debugging of tooling.

• The facility has the function of automatic tool compensation to improve the service life of grinding tools and reduce their wear and tear loss.

• The facility is easy to move by forklift at any time to facilitate the planning of the workshop layout.

• It is suitable for the peripheral operation of the die-casting machine and the automatic integrated operation. It is also suitable for one person to manually load and unload materials and simultaneously operate multiple machines for production.

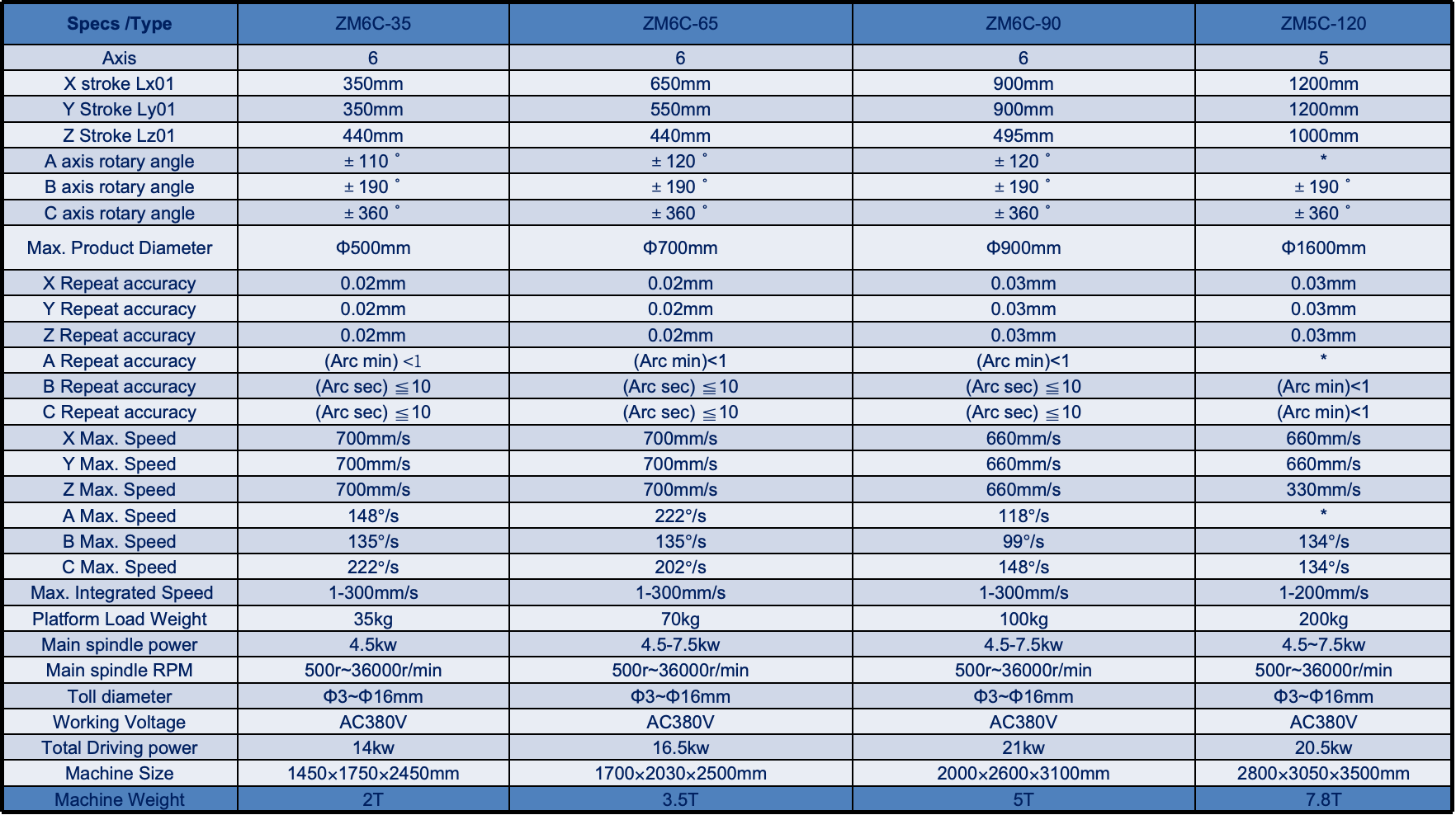

FACILITY SPECIFICATION:

• apan (Omron) special high-performance multi axis control system is adopted.

• Omron servo motor is equipped, which has fast response, smooth running track and accurate position control.

• The system is easy to operate and quick to use. The system can store thousands of programs, which can be called when changing products to avoid repeated programming and improve the utilization rate of facility.

• The main structure of the facility adopts the cast iron mold-opening forming technology. It has high rigidity, high precision, good processing stability, no tool vibration, and fast feed speed and is a special machine tool for grinding and deburring.

High accuracy:

It can be flexibly adjusted and optimized according to the customer's product characteristics and supports visual positioning and

correction functions to

overcome the error of clothing clips. Equipment repeat accuracy≤0.03mm. If necessary, part of the 5-axis machining center can

be completed.

Multi-axis motion:

Multi-axis linkage can complete plane and three-dimensional operations with a variety of tools. The combination of the rigid main

shaft and the floating main shaft can realize thorough grinding and cleaning.

OCP:

The machine is a special machine with an integral structure. The coordinates of the motion axis and jig platform are in a fixed state

for a long time after the first calibration.

The system has a power-off protection function to ensure that the stored operating procedures are not permanently lost.

Fast Speed:

Fast speed and high efficiency. Due to the combined operation of multiple tools, according to the structural characteristics of

the workpiece, the right tool is automatically matched, and even the cutting of the runner can achieve high-speed operation,

and the user's productivity is greatly improved.

Small Volume:

Small size, easy to move, and strong maneuverability, it can finish grinding and cleaning work next to the molding machine,

reducing logistics costs and working damage during transportation.

Energy Saving:

The equipment adopts the working principle of the cutting mode, which generates less dust, and the particles after cutting

can be recycled to enhance the value of waste.

A fully enclosed structure design, high safety factor, smoke detector, automatic fire extinguishing device, and water curtain

filtering system can be added according to user requirements.

Flexible choice of grinding tools:

Parameters

Comparison with Robot solution:

|

ITEM |

ROBOT |

DASEON MACHINE |

|

Flexible adaptation |

Changing models requires re-teaching and programming, which takes an average of 4-6 hours (industry research data), making it difficult to adapt to the trend of multiple varieties and small batches |

Force control closed loop system, adaptive product tolerance ±0.5mm, changeover time <30 minutes |

|

Dust treatment |

An external dust removal system has high energy consumption(7.5kW+) |

Integrated vortex separation + electrostatic adsorption, dust removal efficiency 99.8%, energy consumption reduced to 3kW |

|

Process superiority |

Aluminum chips easily stick to cutting tools, requiring frequent shutdowns for cleaning. The actual measured effective operating time accounts for less than 70%. |

With a power sprayer and air blow system, Prevent metal chips from sticking |

|

Explosion proof for Magnesium |

Conventional equipment cannot meet the requirements |

Fully enclosed explosion-proof cabin + oxygen content monitoring (automatic shutdown when O₂≤5%) |

Machine Structure

Customer Site