Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

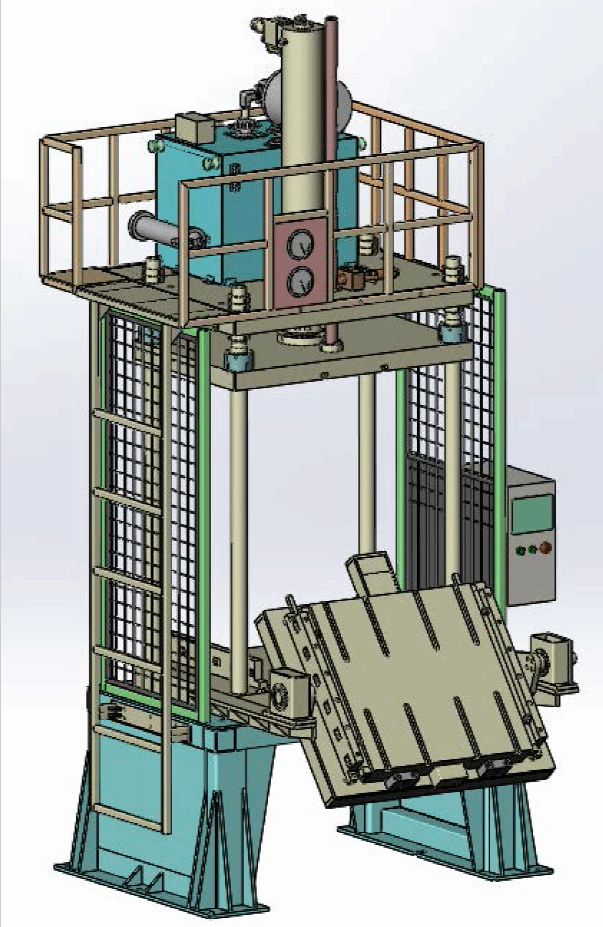

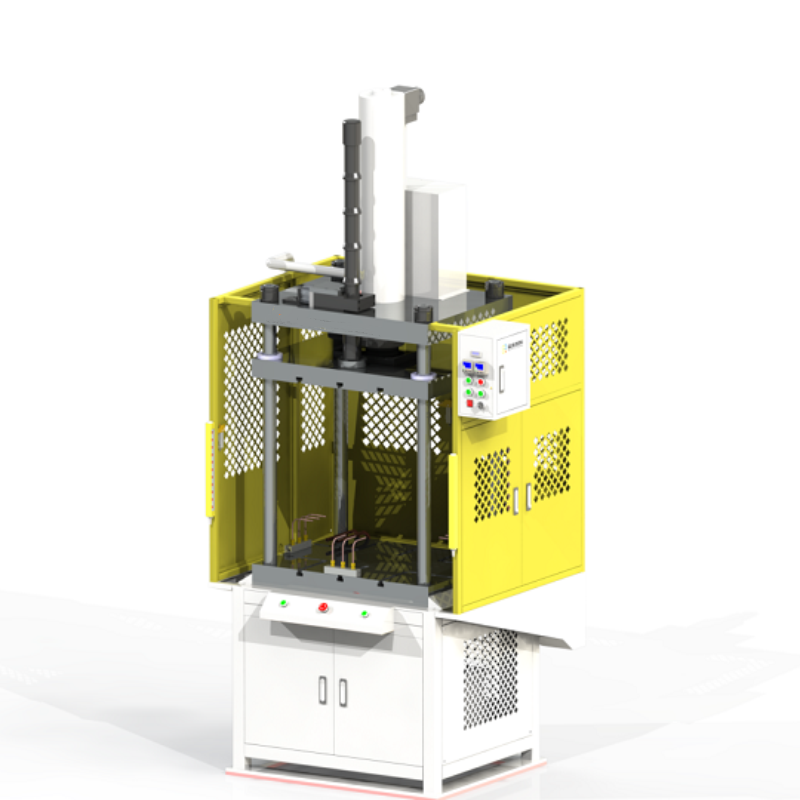

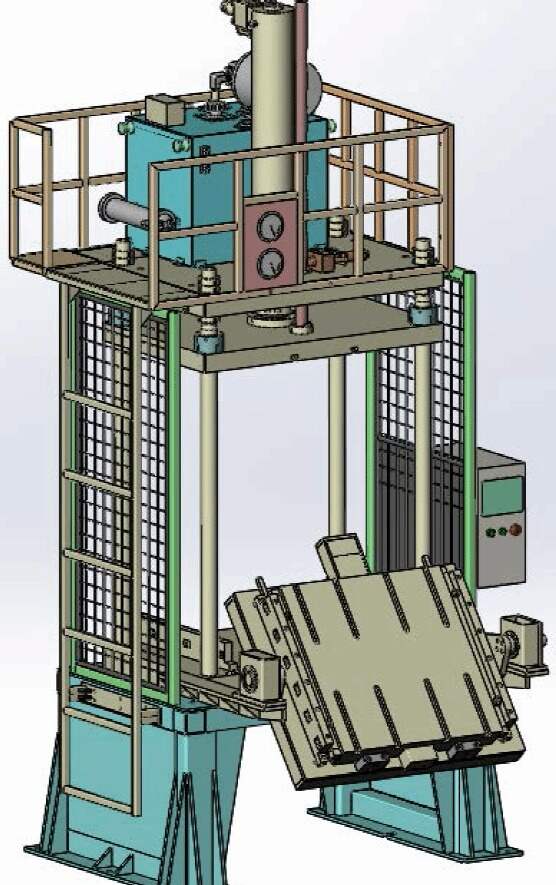

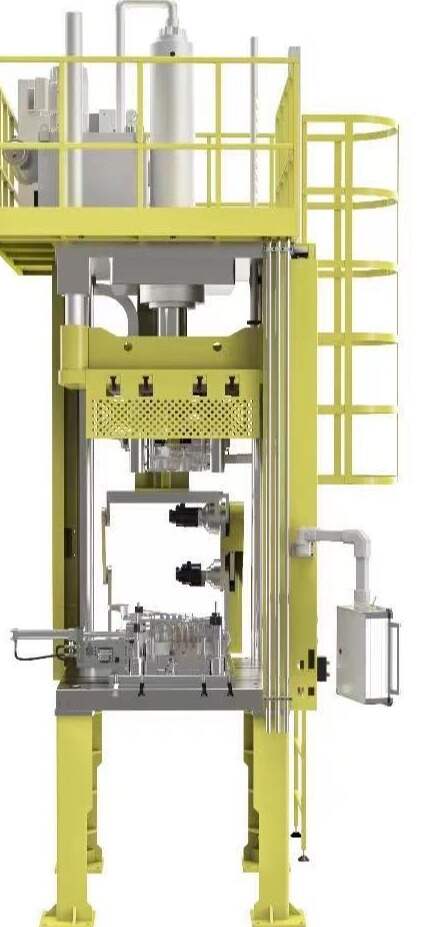

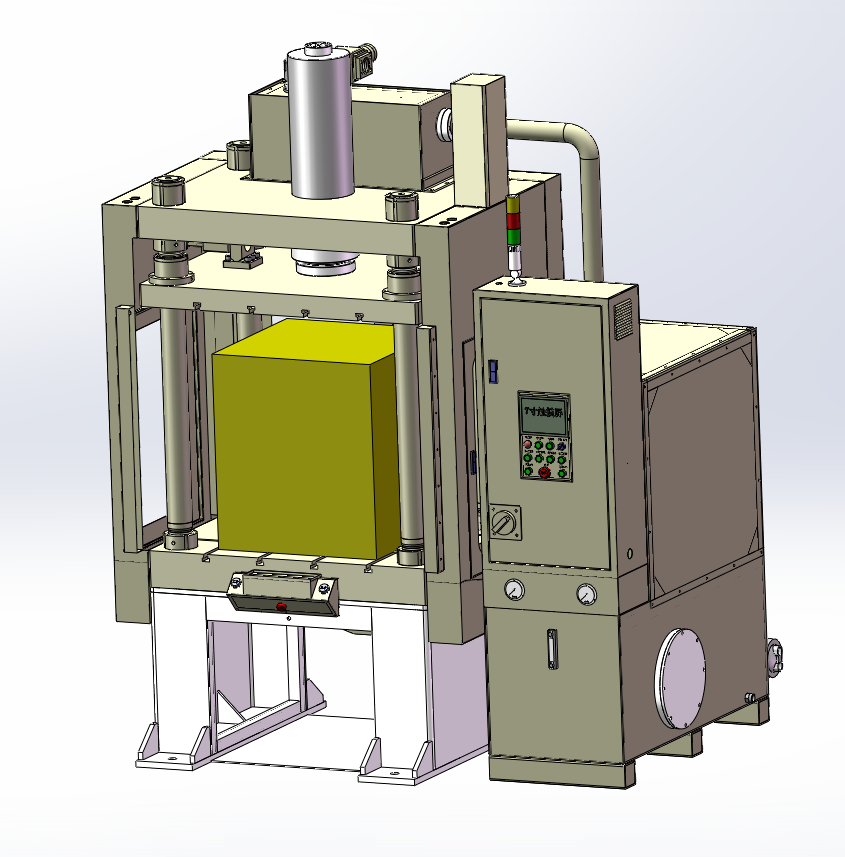

Die Casting Hydraulic Trim Press

20 years of experience in the die casting trim press industry, long-term partnership with die casting machine manufacturers, LK, YIZUMI, HAITIAN, IDRA, BUHLER, etc.

Good reputation from customers, your best choice for die casting hydraulic press. General type, tailor-made, die casting island, press with tray, press with flip, etc.

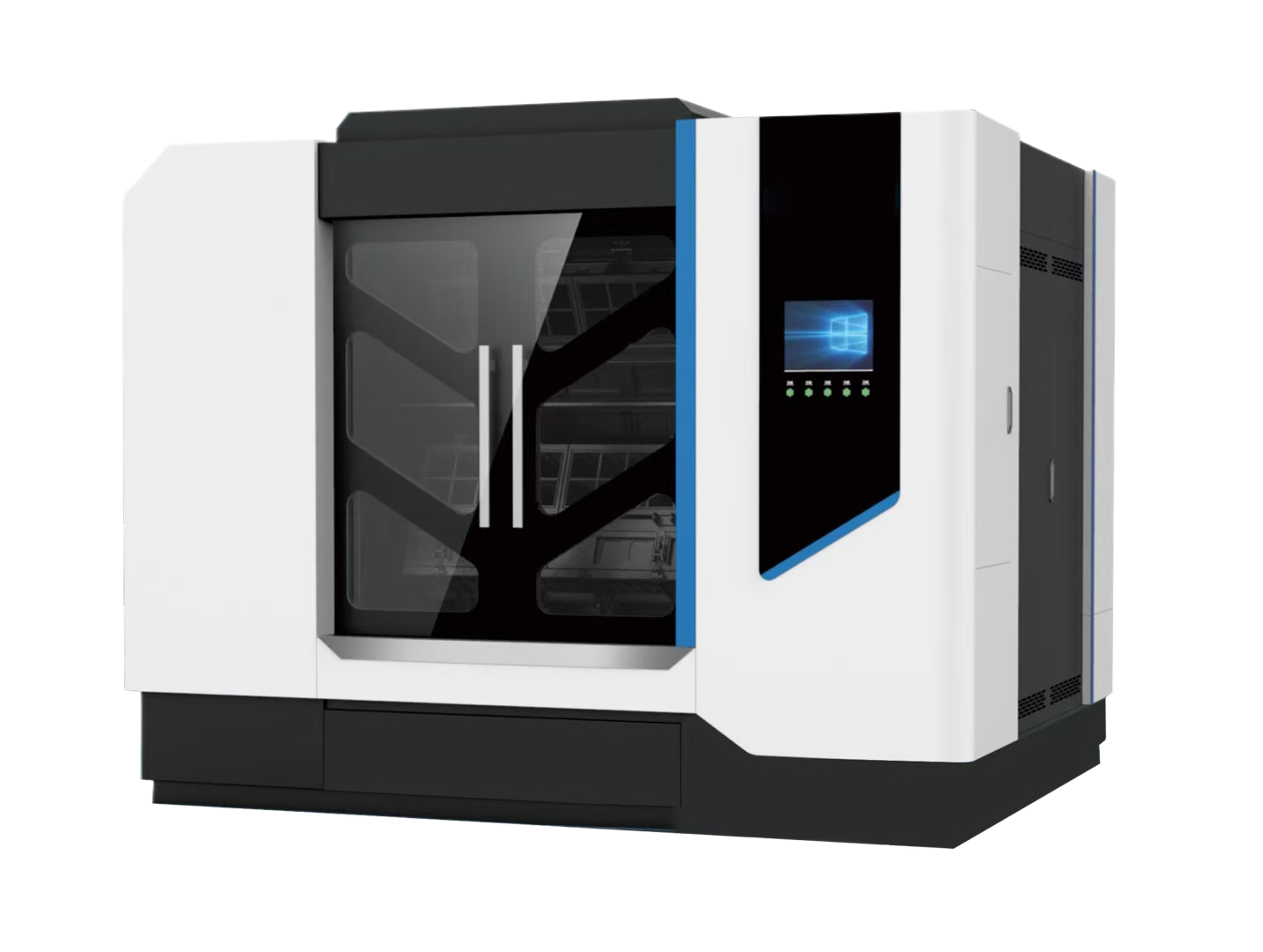

DIE CASTING TRIM PRESS

Machine structure: through finite element analysisguarantee the strength and rigidity of hydraulic press.

Ease Operation: user friendly HMl, ease for setting parameters and recipe storage.Control system:PLc+HMl(Siemens brand), refer to pressing technology requirement set the parameters on HMl such as pressure, position, hold pressure, multi-pressing,etc.

Operation Mode: equipped with independent hydraulicpower pack and electrical system, central operation panelto perform three operation modes including inching,manual semi-automatic.

Accuracy Monitoring: used for linear scale and pressuresensor to monitor the position and pressure, enhance thepressing accuracy.

Position Accuracy: repeatability of ram position achieve to ±0.03mm, control the scrap rate of products caused bymachine accuracy.

Pressing Accuracy: repeatability of ram pressure achieveto ±3%,control the scrap rate of products caused bymachine accuracy.

Energy Saving: used of servo motor driving system canachieve energy saving 30-50%.

Low Noise Level: used of servo motor driving system, fulfilldifferent speed and pressure of pressing requirement.ensures the stability of movement, lower noise level.Efficiency:each auxiliary unit can work independent in production,enhances the productivity.

Selectivity: single station or two stations can be selected! different function of auxiliary unit can be selected.

Automatic Production: different type of auxiliary production device can be designed as customelrequested.

(Induction motor driving system as option)

Features

Using a built-in high-speed cylinder has a fast falling speed and high production efficiency.

Four columns are made from high-strength alloy steel with hard chrome plated surface and good abrasion resistance.

Pressure stroke and pressurizing time can be adjusted according to processing requirements.

Optional configuration: protective shield anti-drop device blowing and removing scraps device, etc.

Advantages of our machine

With Servo system

DASEON Hydraulic press with servo system,can bring you 10 kinds Advantages as below:

1. Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2. English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% – 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

it means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service. Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.

We could supply not only custom machine,molds,robot arm(manipulator),auto feeder process technology, and other relative machines but also a full production line service.

The main components are imported from USA,German, Japan and Taiwan .

Our factory have specialized in independent development and producing hydraulic press for over 20 years. So the product is stable and high quality.

Machine body, bending structure , much stronger than the common welding structure .

Oil pipe, using Clip-on structure , much tight than common welding structure. Prevent oil leakage.

Integrated oil manifold block, much easier to check machine and repair machine.

Key Components Photo

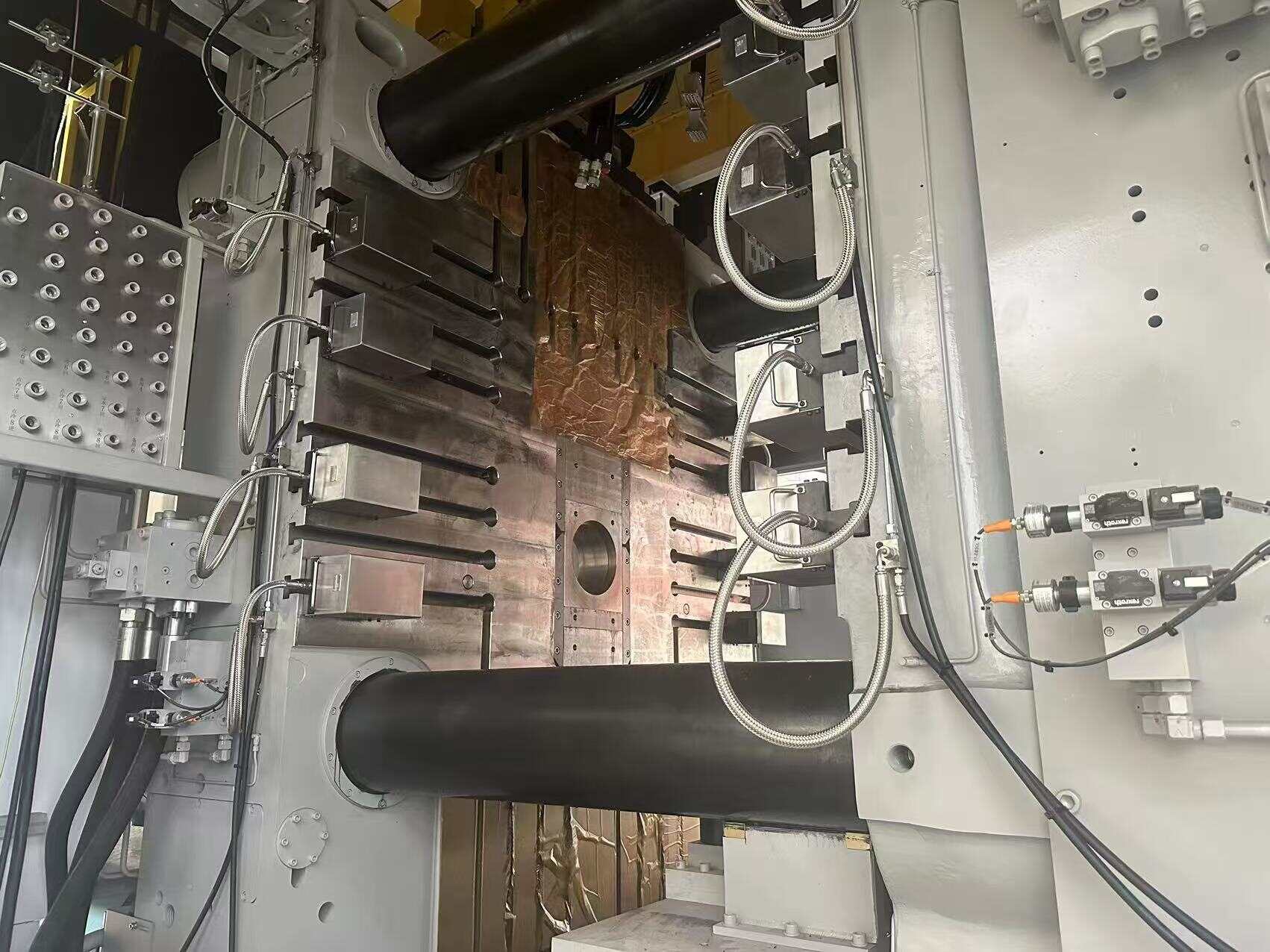

Machine Platen

Cylinder

Partner relationship with top die casting machine brands.

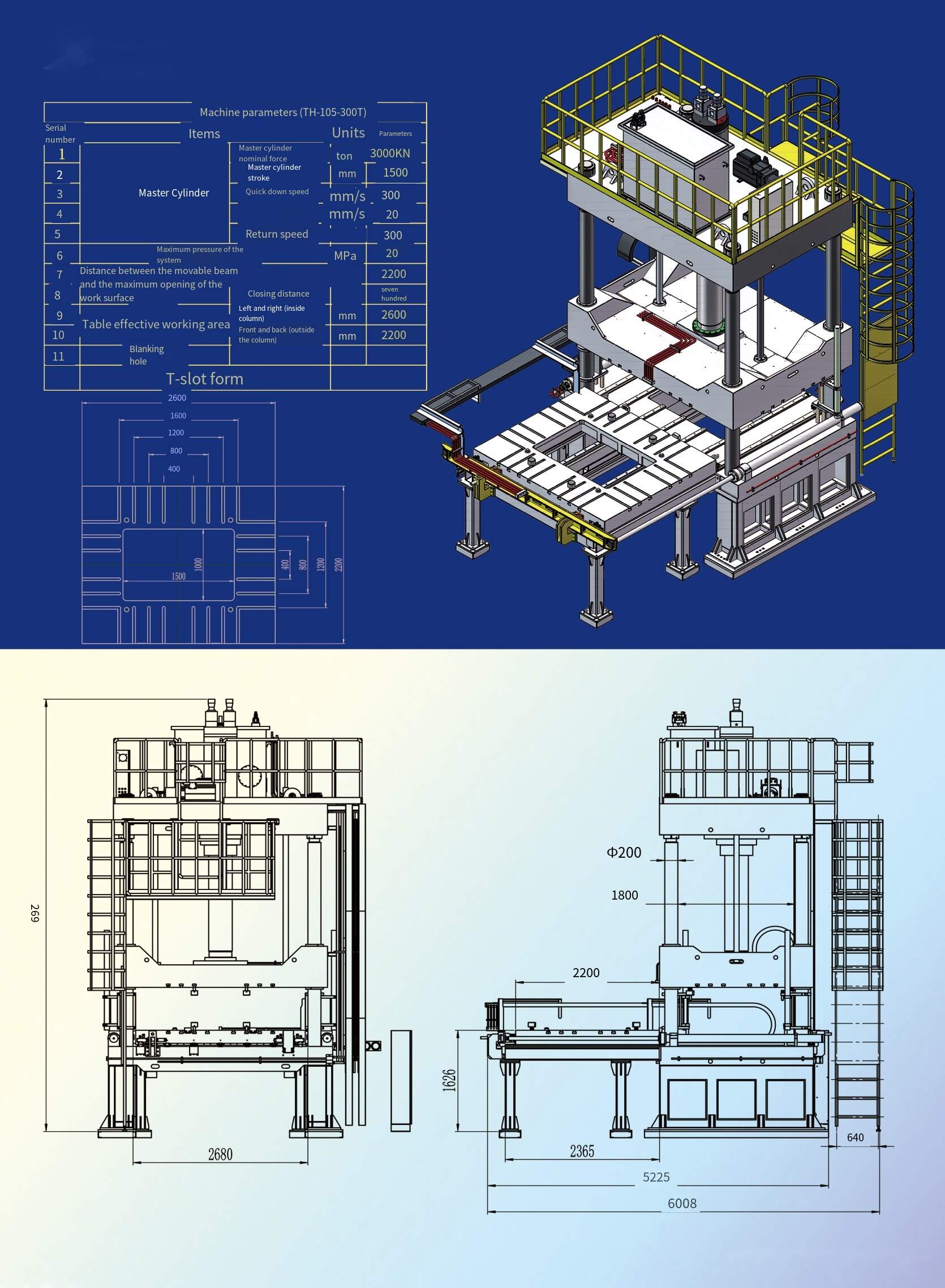

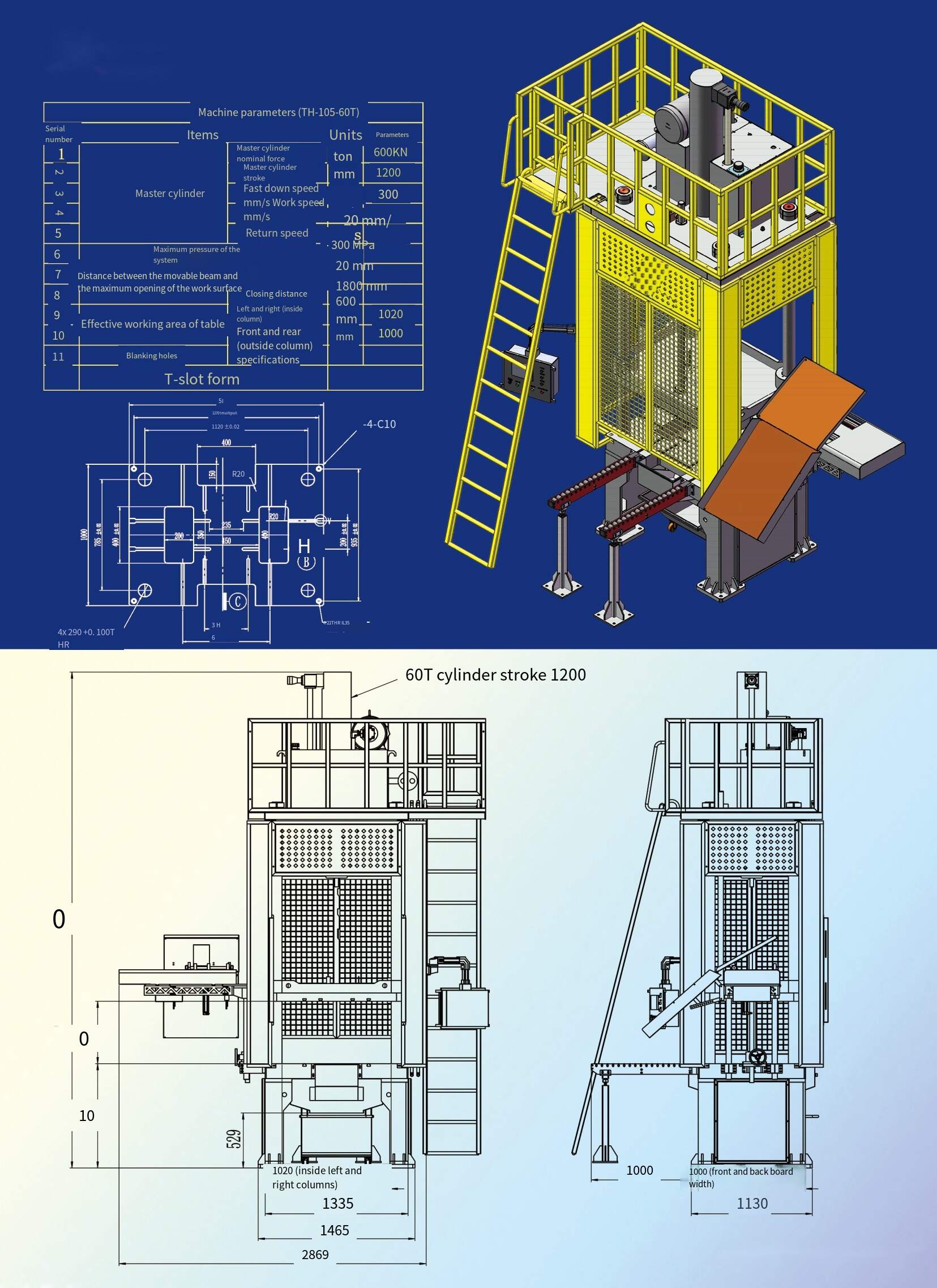

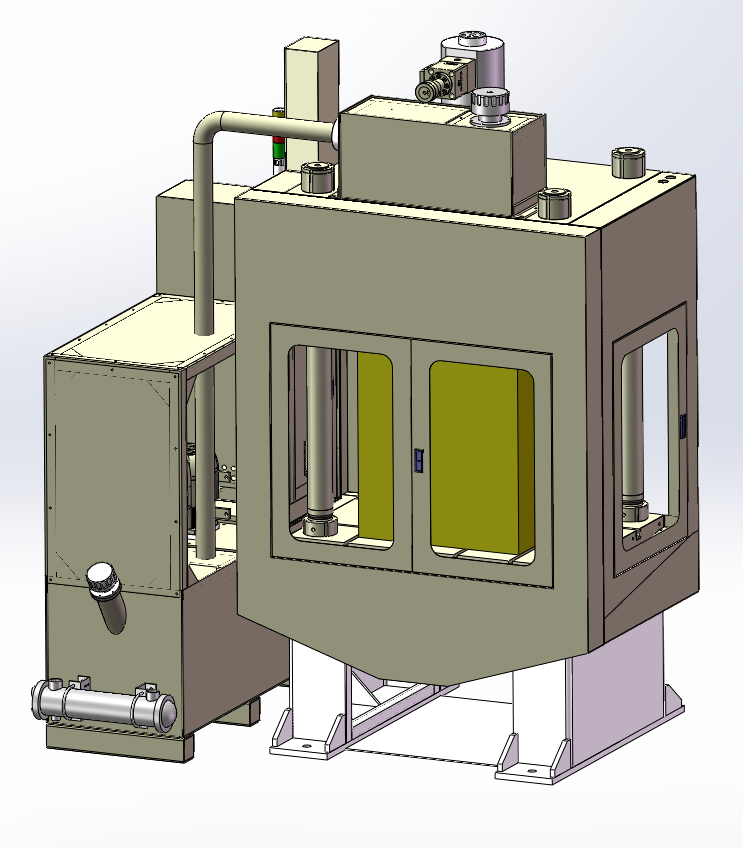

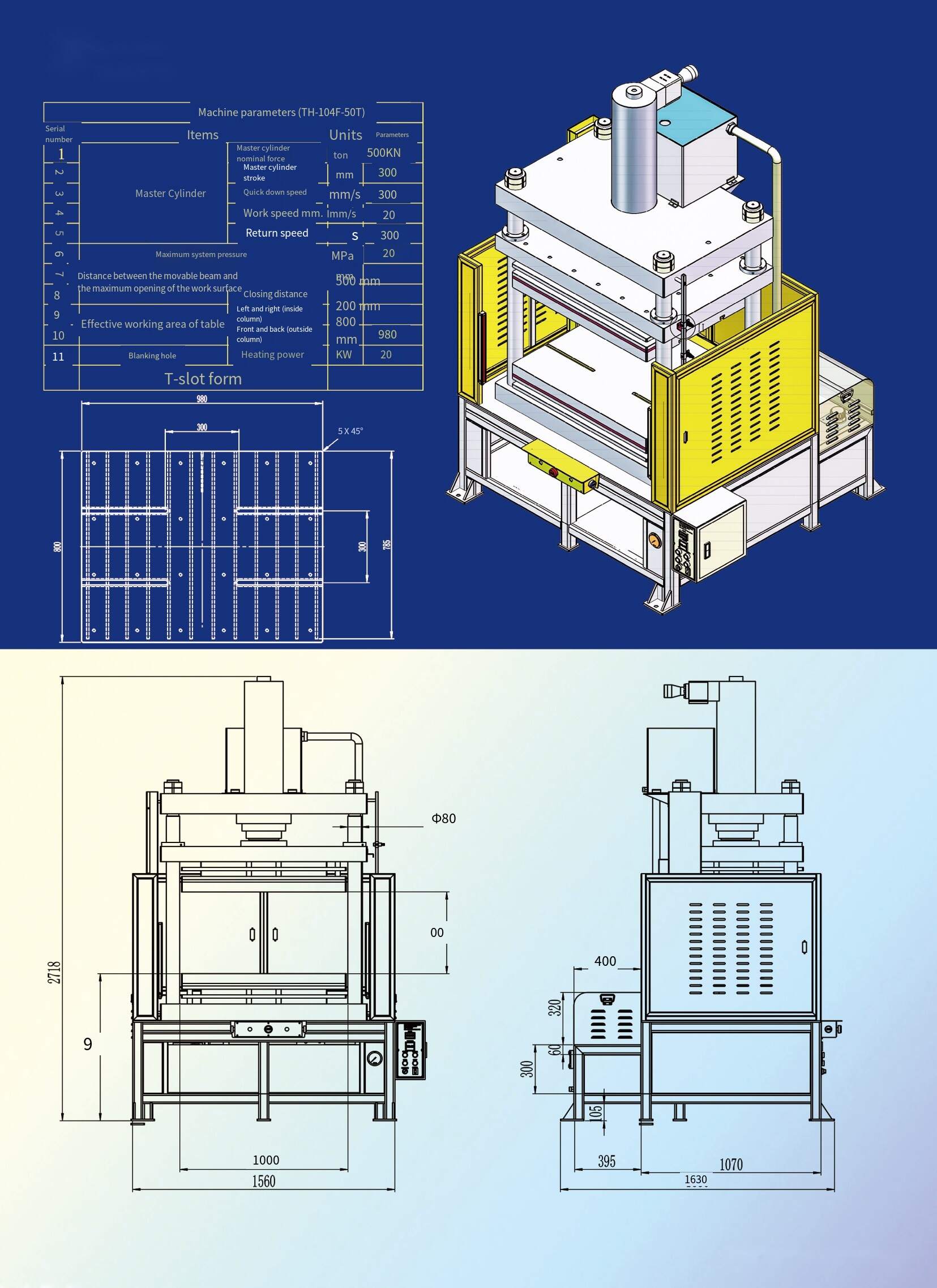

Parameters for different models

50T

200T

60T

More models detail please contact us!