Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

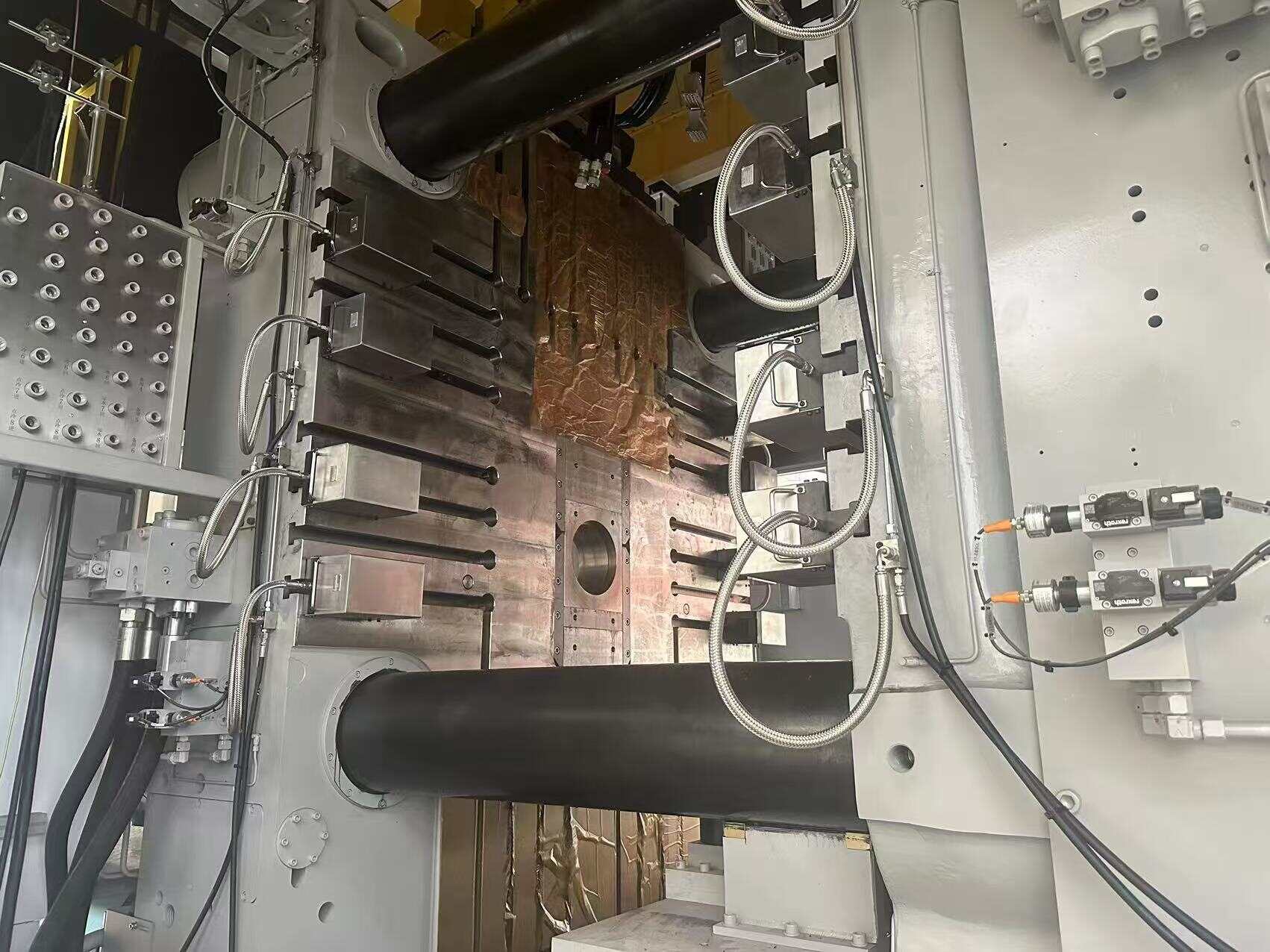

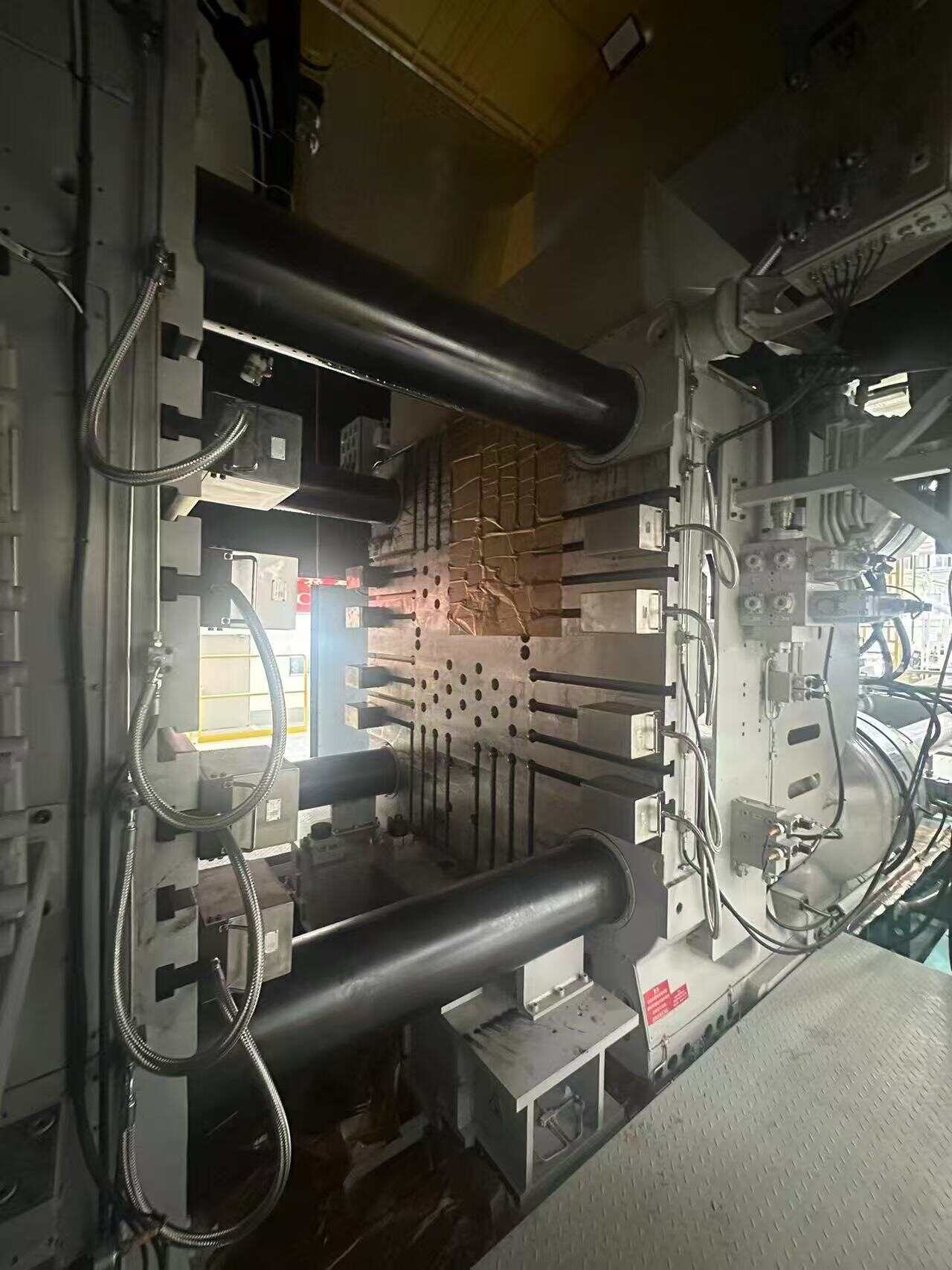

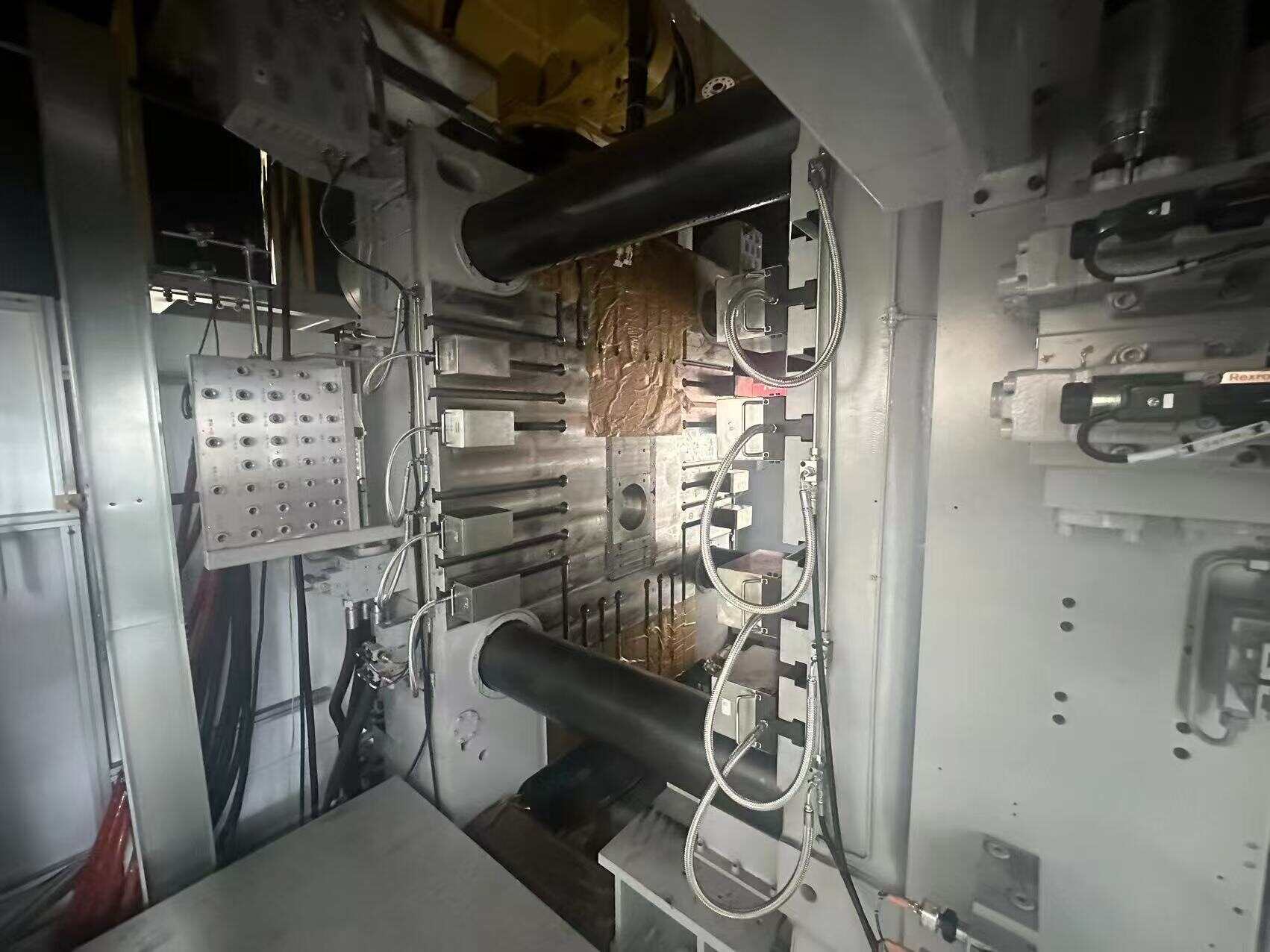

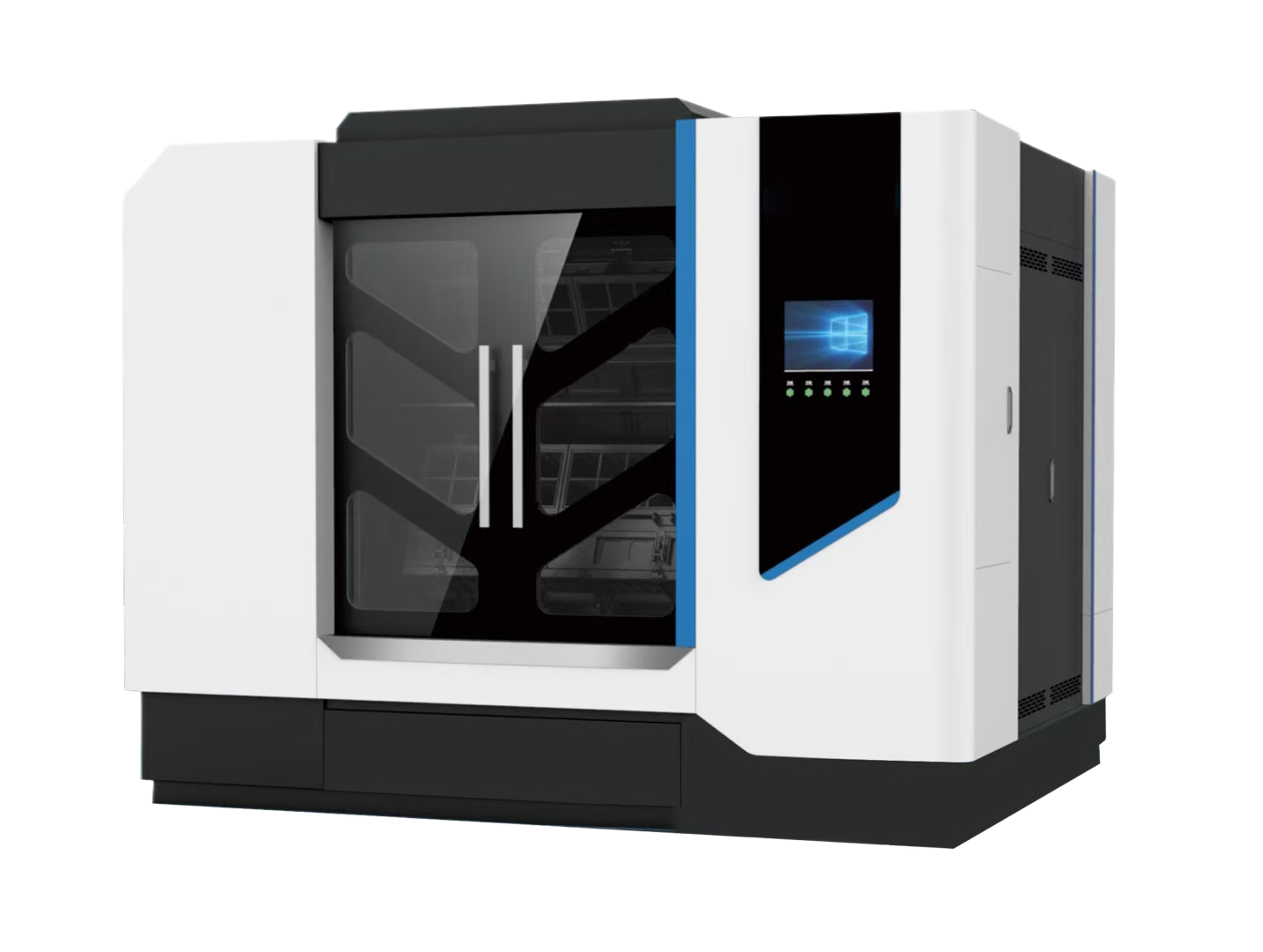

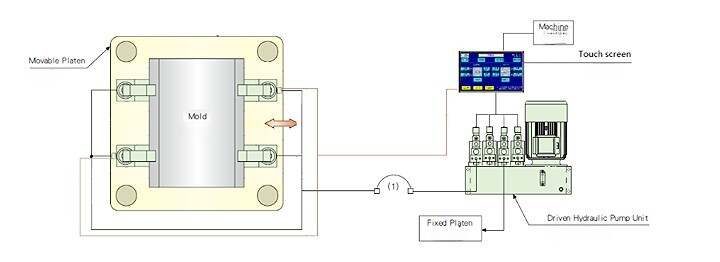

Fast mold change system

Our fast mold change system, fast die changing system, provides a method of loosening and removing a complete tooling system to replace traditional manual die changes. Consisting of an electric drive hydraulic system, fast response, die gripper, and electronically controlled operator box, the complete system simplifies the clamping/unclamping and die change process, making die changes on presses easier and safer.

Quick Die Change System

Our fast mold change system, fast die changing system, provides a method of loosening and removing a complete tooling system to replace traditional manual die changes. Consisting of an electric drive hydraulic system, fast response, die gripper, and electronically controlled operator box, the complete system simplifies the clamping, unclamping, and die change process, making die changes on presses easier and safer.

During a die change on a die casting press, the efficiency of the die change process is very low. Traditional die change processes typically utilize machinery to manually loosen and tighten bolts, which can potentially cause injury to workers. In addition, quality and productivity are compromised due to wasted downtime.

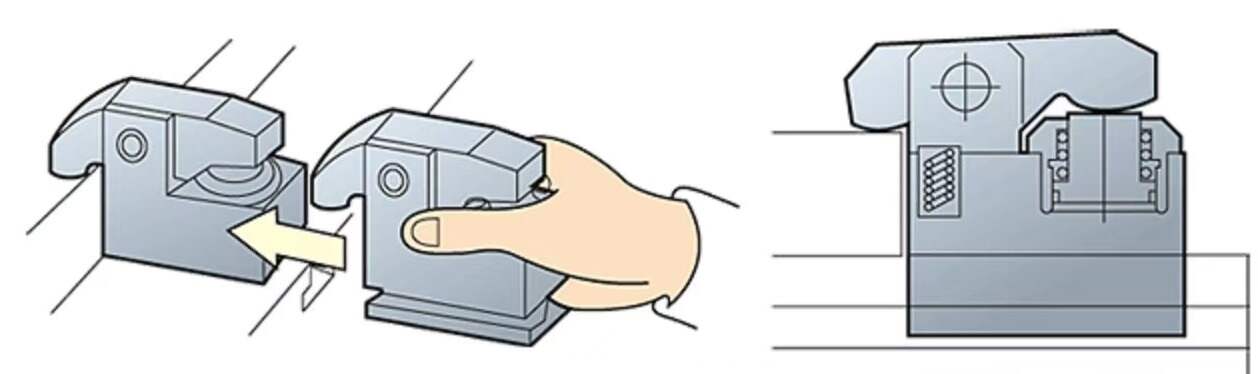

Die clamp features

- Quick and easy die changing

- Very high clamping pressure

- High opening and closing speeds

- Easy insertion and removal

- Safer Operations

- Increased productivity

This lever-type clamp does not require a U-slot on the die shoe; it can be used in a wide range of applications. This type of Die clamp is machined to fit into the T-slot of the bolster for extra secure positioning. The flange-mount model Die Clamps can be bolted onto the bolster, and the automatic slider model Die Clamps make remote automatic operation possible.

All DASEON Fast Mold Change Systems use high-quality Die Clamps for very secure clamping, quick mold changing, and safer operations.

These clamps can fasten Molds whether they are changed vertically or horizontally.

There is also a range of different Die Clamps available to suit your injection molding or mold casting requirements.

The Die Clamps are machined to fit into the T-slot of the bolster for extra secure positioning. The flange-mount model Die Clamps can be bolted onto the bolster, and the automatic slider model Die Clamps make remote automatic operation possible.

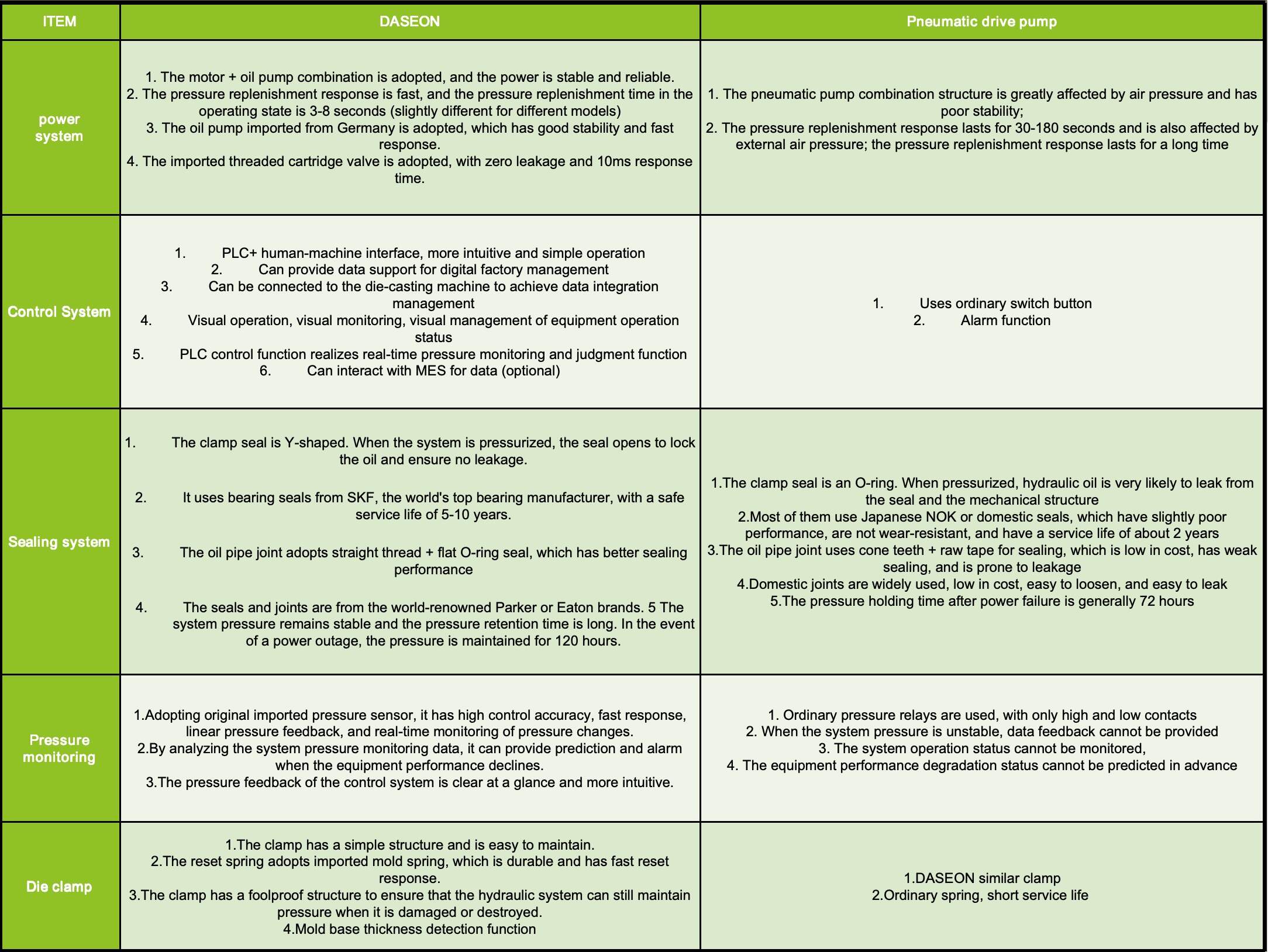

Comparison to pneumatic hydraulic clamp system

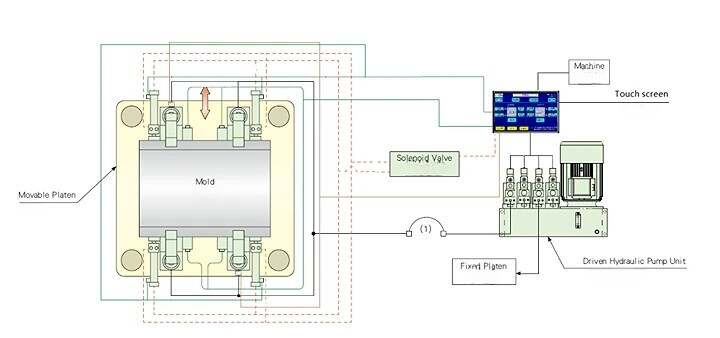

System Structure

Fully automatic

Semi-automatic

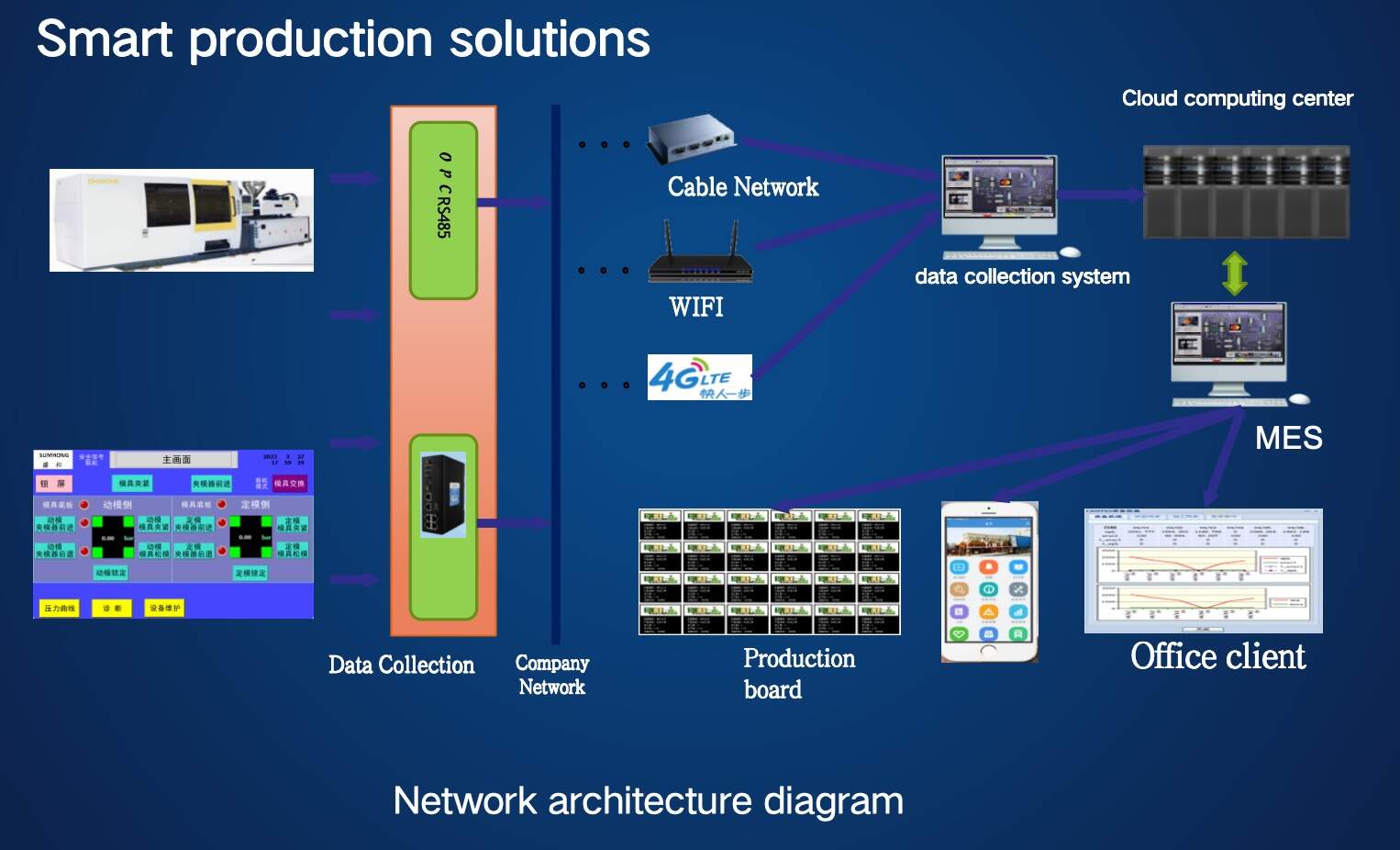

Smart production system